Page 385 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 385

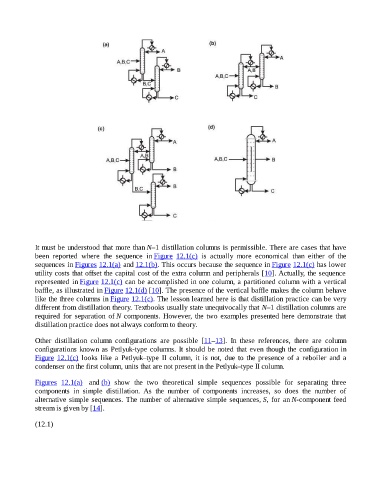

It must be understood that more than N–1 distillation columns is permissible. There are cases that have

been reported where the sequence in Figure 12.1(c) is actually more economical than either of the

sequences in Figures 12.1(a) and 12.1(b). This occurs because the sequence in Figure 12.1(c) has lower

utility costs that offset the capital cost of the extra column and peripherals [10]. Actually, the sequence

represented in Figure 12.1(c) can be accomplished in one column, a partitioned column with a vertical

baffle, as illustrated in Figure 12.1(d) [10]. The presence of the vertical baffle makes the column behave

like the three columns in Figure 12.1(c). The lesson learned here is that distillation practice can be very

different from distillation theory. Textbooks usually state unequivocally that N–1 distillation columns are

required for separation of N components. However, the two examples presented here demonstrate that

distillation practice does not always conform to theory.

Other distillation column configurations are possible [11–13]. In these references, there are column

configurations known as Petlyuk-type columns. It should be noted that even though the configuration in

Figure 12.1(c) looks like a Petlyuk–type II column, it is not, due to the presence of a reboiler and a

condenser on the first column, units that are not present in the Petlyuk–type II column.

Figures 12.1(a) and (b) show the two theoretical simple sequences possible for separating three

components in simple distillation. As the number of components increases, so does the number of

alternative simple sequences. The number of alternative simple sequences, S, for an N-component feed

stream is given by [14].

(12.1)