Page 390 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 390

two “pure” products. The McCabe-Thiele construction is illustrated in Figures 12.5(c) and 12.5(d). In

this illustration, increasing the system pressure lowers the azeotropic composition of A. The McCabe-

Thiele construction in Figure 12.5(d) is at a higher pressure than that in Figure 12.5(c). Therefore, for the

case illustrated, the feed is distilled in one column to produce “pure” B and a near-azeotropic distillate

(D ). This distillate is then pumped to a higher pressure, which lowers the azeotropic composition. At a

1

suitable pressure, the distillate from the first column is now above the azeotropic composition, and a

second column is then used to purify A. “Pure” A is the bottoms product of the second column because of

the reversal in volatilities caused by the azeotrope. The near-azeotropic distillate (D ) is recycled to the

2

first column.

A related method for pressure-sensitive azeotropes is to run only one column at vacuum conditions. If the

equilibrium behavior is favorable, the azeotrope will be at a mole fraction of A approaching unity.

Depending on the desired purity of component A, the maximum possible distillate composition may be

sufficient.

It is important to remember that pressure-swing methods are applicable only when the azeotropic

composition is highly pressure sensitive. Although there are examples of this behavior, it is actually quite

rare.

Azeotropes in Ternary Systems. In binary systems, the McCabe-Thiele method provides a conceptual

representation of the distillation process. In ternary systems, there is a method that provides a similar

conceptual representation. It is called the boundary value design method (BVDM), and it is particularly

useful for conceptualizing azeotropic distillation in ternary systems. This method is introduced here;

however, the reader seeking a more in-depth treatment of this method and all aspects of azeotropic

distillation should consult the definitive reference in the field [17].

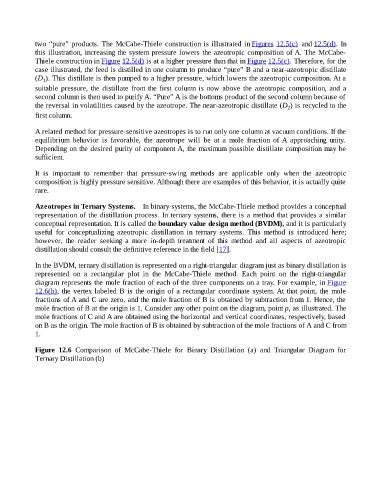

In the BVDM, ternary distillation is represented on a right-triangular diagram just as binary distillation is

represented on a rectangular plot in the McCabe-Thiele method. Each point on the right-triangular

diagram represents the mole fraction of each of the three components on a tray. For example, in Figure

12.6(b), the vertex labeled B is the origin of a rectangular coordinate system. At that point, the mole

fractions of A and C are zero, and the mole fraction of B is obtained by subtraction from 1. Hence, the

mole fraction of B at the origin is 1. Consider any other point on the diagram, point p, as illustrated. The

mole fractions of C and A are obtained using the horizontal and vertical coordinates, respectively, based

on B as the origin. The mole fraction of B is obtained by subtraction of the mole fractions of A and C from

1.

Figure 12.6 Comparison of McCabe-Thiele for Binary Distillation (a) and Triangular Diagram for

Ternary Distillation (b)