Page 74 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 74

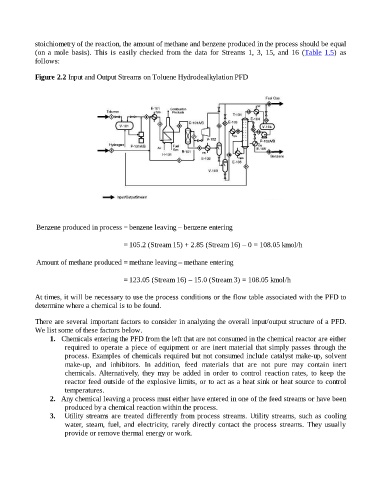

stoichiometry of the reaction, the amount of methane and benzene produced in the process should be equal

(on a mole basis). This is easily checked from the data for Streams 1, 3, 15, and 16 (Table 1.5) as

follows:

Figure 2.2 Input and Output Streams on Toluene Hydrodealkylation PFD

Benzene produced in process = benzene leaving – benzene entering

= 105.2 (Stream 15) + 2.85 (Stream 16) – 0 = 108.05 kmol/h

Amount of methane produced = methane leaving – methane entering

= 123.05 (Stream 16) – 15.0 (Stream 3) = 108.05 kmol/h

At times, it will be necessary to use the process conditions or the flow table associated with the PFD to

determine where a chemical is to be found.

There are several important factors to consider in analyzing the overall input/output structure of a PFD.

We list some of these factors below.

1. Chemicals entering the PFD from the left that are not consumed in the chemical reactor are either

required to operate a piece of equipment or are inert material that simply passes through the

process. Examples of chemicals required but not consumed include catalyst make-up, solvent

make-up, and inhibitors. In addition, feed materials that are not pure may contain inert

chemicals. Alternatively, they may be added in order to control reaction rates, to keep the

reactor feed outside of the explosive limits, or to act as a heat sink or heat source to control

temperatures.

2. Any chemical leaving a process must either have entered in one of the feed streams or have been

produced by a chemical reaction within the process.

3. Utility streams are treated differently from process streams. Utility streams, such as cooling

water, steam, fuel, and electricity, rarely directly contact the process streams. They usually

provide or remove thermal energy or work.