Page 75 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 75

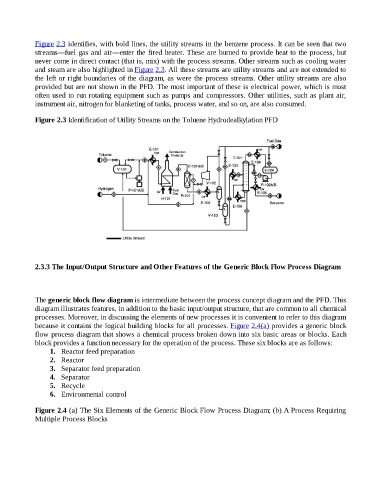

Figure 2.3 identifies, with bold lines, the utility streams in the benzene process. It can be seen that two

streams—fuel gas and air—enter the fired heater. These are burned to provide heat to the process, but

never come in direct contact (that is, mix) with the process streams. Other streams such as cooling water

and steam are also highlighted in Figure 2.3. All these streams are utility streams and are not extended to

the left or right boundaries of the diagram, as were the process streams. Other utility streams are also

provided but are not shown in the PFD. The most important of these is electrical power, which is most

often used to run rotating equipment such as pumps and compressors. Other utilities, such as plant air,

instrument air, nitrogen for blanketing of tanks, process water, and so on, are also consumed.

Figure 2.3 Identification of Utility Streams on the Toluene Hydrodealkylation PFD

2.3.3 The Input/Output Structure and Other Features of the Generic Block Flow Process Diagram

The generic block flow diagram is intermediate between the process concept diagram and the PFD. This

diagram illustrates features, in addition to the basic input/output structure, that are common to all chemical

processes. Moreover, in discussing the elements of new processes it is convenient to refer to this diagram

because it contains the logical building blocks for all processes. Figure 2.4(a) provides a generic block

flow process diagram that shows a chemical process broken down into six basic areas or blocks. Each

block provides a function necessary for the operation of the process. These six blocks are as follows:

1. Reactor feed preparation

2. Reactor

3. Separator feed preparation

4. Separator

5. Recycle

6. Environmental control

Figure 2.4 (a) The Six Elements of the Generic Block Flow Process Diagram; (b) A Process Requiring

Multiple Process Blocks