Page 94 - Analysis, Synthesis and Design of Chemical Processes, Third Edition

P. 94

Important Points

From this margin analysis, it is clear that the amount of DEE produced should be optimized, because

making ethylene is far less profitable. In addition, the maximum amount of DEE that the market can

support is not currently being produced. Therefore, supplementing the feed with ethanol should be

considered.

Because the main feed stream contains both reactants and an impurity (water), separation or purification

of the feed prior to processing should be considered.

In order to minimize the production of by-products (ethylene), the selectivity of the DEE reaction should

be optimized.

Alternative 1

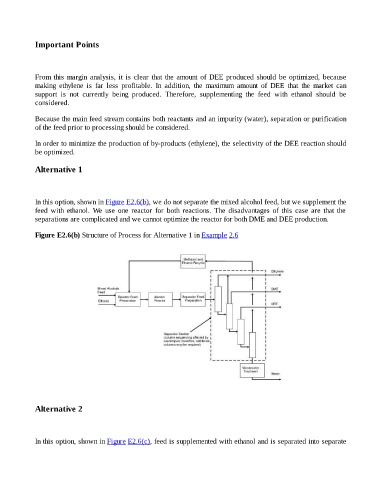

In this option, shown in Figure E2.6(b), we do not separate the mixed alcohol feed, but we supplement the

feed with ethanol. We use one reactor for both reactions. The disadvantages of this case are that the

separations are complicated and we cannot optimize the reactor for both DME and DEE production.

Figure E2.6(b) Structure of Process for Alternative 1 in Example 2.6

Alternative 2

In this option, shown in Figure E2.6(c), feed is supplemented with ethanol and is separated into separate