Page 19 - Analytical method for food addtives

P. 19

4 Analytical methods for food additives

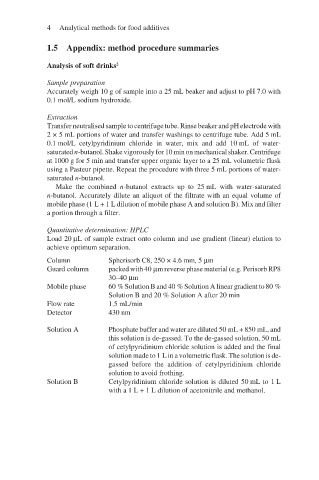

1.5 Appendix: method procedure summaries

Analysis of soft drinks 2

Sample preparation

Accurately weigh 10 g of sample into a 25 mL beaker and adjust to pH 7.0 with

0.1 mol/L sodium hydroxide.

Extraction

Transfer neutralised sample to centrifuge tube. Rinse beaker and pH electrode with

2 × 5 mL portions of water and transfer washings to centrifuge tube. Add 5 mL

0.1 mol/L cetylpyridinium chloride in water, mix and add 10 mL of water-

saturated n-butanol. Shake vigorously for 10 min on mechanical shaker. Centrifuge

at 1000 g for 5 min and transfer upper organic layer to a 25 mL volumetric flask

using a Pasteur pipette. Repeat the procedure with three 5 mL portions of water-

saturated n-butanol.

Make the combined n-butanol extracts up to 25 mL with water-saturated

n-butanol. Accurately dilute an aliquot of the filtrate with an equal volume of

mobile phase (1 L + 1 L dilution of mobile phase A and solution B). Mix and filter

a portion through a filter.

Quantitative determination: HPLC

Load 20 µL of sample extract onto column and use gradient (linear) elution to

achieve optimum separation.

Column Spherisorb C8, 250 × 4.6 mm, 5 µm

Guard column packed with 40 µm reverse phase material (e.g. Perisorb RP8

30–40 µm

Mobile phase 60 % Solution B and 40 % Solution A linear gradient to 80 %

Solution B and 20 % Solution A after 20 min

Flow rate 1.5 mL/min

Detector 430 nm

Solution A Phosphate buffer and water are diluted 50 mL + 850 mL, and

this solution is de-gassed. To the de-gassed solution, 50 mL

of cetylpyridinium chloride solution is added and the final

solution made to 1 L in a volumetric flask. The solution is de-

gassed before the addition of cetylpyridinium chloride

solution to avoid frothing.

Solution B Cetylpyridinium chloride solution is diluted 50 mL to 1 L

with a 1 L + 1 L dilution of acetonitrile and methanol.