Page 236 - Analytical method for food addtives

P. 236

E320: BHA 157

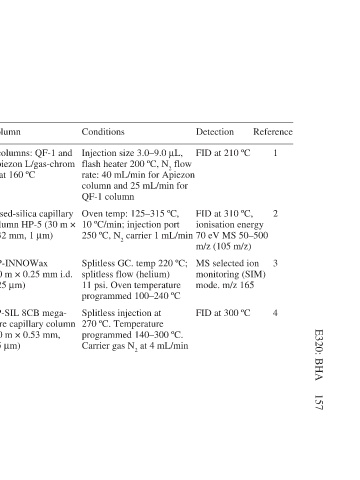

Reference 1 2 3 4

Detection FID at 210 ºC FID at 310 ºC, ionisation energy eV MS 50–500 70 m/z (105 m/z) MS selected ion monitoring (SIM) mode. m/z 165 FID at 300 ºC

Injection size 3.0–9.0 µL, flash heater 200 ºC, N 2 flow rate: 40 mL/min for Apiezon column and 25 mL/min for Oven temp: 125–315 ºC, 10 ºC/min; injection port 250 ºC, N 2 carrier 1 mL/min Splitless GC. temp 220 ºC; splitless flow (helium) 11 psi. Oven temperature programmed 100–240 ºC Splitless injection at 270 ºC

Conditions QF-1 column m ×

2 columns: QF-1 and Apiezon L/gas-chrom Fused-silica capillary column HP-5 (30 mm, 1 µm) HP-INNOWax mm i.d. m × 0.25 CP-SIL 8CB mega- bore capillary column mm, m × 0.53

Column Q at 160 ºC 0.32 (30 0.25 µm) (30 1.5 µm)

Summary of methods for BHA in foods Sample preparation/extraction Ground sample placed in chromato- graphic column and eluted with CS 2 , di-BHA internal standard added to eluate. Evaporate to <5.0 mL under N 2 . Make up to 5.0 mL Samples manually extracted with a mixture of solvents then subjected to continuous SPE system Solid

Table 12.1 (a) Matrix Method Cereals GC Fatty foods GC Foods GC–MS (SIM) Edible fats GC and oils