Page 213 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 213

66131_Ludwig_CH10F 5/30/2001 4:35 PM Page 176

176 Applied Process Design for Chemical and Petrochemical Plants

Now, the h b coefficient can be used with the overall U equa-

tion, including shell-side fouling, to calculate a final overall

coefficient for boiling.

The maximum flux equation of Zuber 128 is suggested as

another check for kettle reboilers:

D b L g 1 L v 2 0.25

q max 176c dp v c d (10-164)

2

A n v

where

q max tube bundle maximum flux, Btu/hr-ft 2

D b tube bundle diameter, ft

L length of tube bundle, straight tube, or average for

U-bundle, ft

A n net effective total bundle outside tube surface area,

ft 2

8

g gravitational constant, 4.17 10 ft/hr 2

The usual range of q max for organic fluids is 15,000—25,000

2

Btu/hr (ft ). For aqueous solutions, the range is 30,000—

40,000 Btu/hr (ft )

2

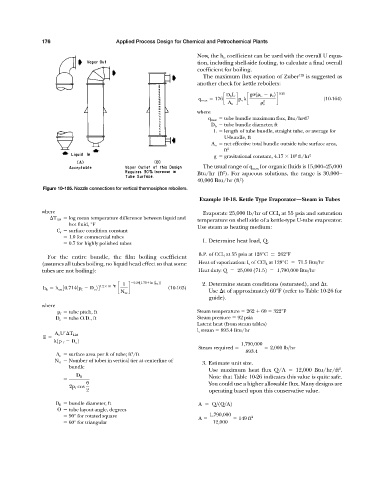

Figure 10-105. Nozzle connections for vertical thermosiphon reboilers.

Example 10-18. Kettle Type Evaporator—Steam in Tubes

where Evaporate 25,000 lb/hr of CCl 4 at 55 psia and saturation

T LM log mean temperature difference between liquid and

temperature on shell side of a kettle-type U-tube evaporator.

hot fluid, °F

Use steam as heating medium:

C s surface condition constant

1.0 for commercial tubes

1. Determine heat load, Q.

0.7 for highly polished tubes

B.P. of CCl 4 at 55 psia at 128°C 262°F

For the entire bundle, the film boiling coefficient

(assumes all tubes boiling, no liquid head effect so that some Heat of vaporization: l v of CCl 4 at 128°C 71.5 Btu>hr

tubes are not boiling): Heat duty: Q 25,000 171.52 1,790,000 Btu>hr

1

1 0.2431.75 ln 1 Nvc 24 2. Determine steam conditions (saturated), and t.

5

h b h on 30.7141p f D o 24 4.2 10 E c d (10-163)

Use t of approximately 60°F (refer to Table 10-26 for

N vc

guide).

where

p f tube pitch, ft Steam temperature 262 60 322°F

D o tube O.D., ft Steam pressure 92 psia

Latent heat (from steam tables)

l v steam 893.4 Btu/hr

A o U¿ T LM

E

1p f D o 2 1,790,000

Steam required 2,000 lb>hr

893.4

2

A o surface area per ft of tube; ft /ft

N vc Number of tubes in vertical tier at centerline of

3. Estimate unit size.

bundle

2

Use maximum heat flux Q/A 12,000 Btu/hr/ft .

D B Note that Table 10-26 indicates this value is quite safe.

You could use a higher allowable flux. Many designs are

2p f cos

2 operating based upon this conservative value.

D B bundle diameter, ft A Q>1Q>A2

tube layout angle, degrees

90° for rotated square 1,790,000 2

A 149 ft

60° for triangular 12,000