Page 297 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 297

66131_Ludwig_CH10G 5/30/2001 4:41 PM Page 259

Heat Transfer 259

0.016–0.014 in. The effect of mechanical bond on heat water. In some situations, the air-cooled unit can be carried to

transfer resistance is discussed by Gardner. 50 within 20–25°F of the dry bulb air temperature if this is the

It is helpful to the manufacturer for the purchaser to spec- desired endpoint rather than adding a small trim cooler.

72

ify any conditions that are peculiar to the plant’s warehouse Kern has studied optimum trim cooler conditions. As the

stock of tubes or process controlled preferences: temperature approach to the ambient air decreases, the

power consumption increases rapidly at constant exchanger

1. Preferred bare tube O.D. and gage, giving minimum surface. This balance of first cost vs. operating cost is one of

average wall thickness. the key comparisons in evaluating these units.

2. Seamless or resistance welded base tube. Because surface area affects the first cost much more than

3. Fin material preferred from atmospheric corrosion the normally required horsepower (driver), the selection of

standpoint. the proper unit is a function of the relative change in these

two items for a fixed heat duty. The optimum design gives

the lowest total costs (first, operating, and maintenance)

General Application over the life of the unit, taken in many instances as 15 years

6

or longer. Fan horsepower runs 2–5 hp per 10 Btu/hr. 63

Air-cooled units have been successfully and economically First costs range from 25–150% of cooling tower systems

used in liquid cooling for compressor engine and jacket water with an average indicated at greater than 30%. 115

and other recirculating systems, petroleum fractions, oils, etc., Although these units find initial application in areas of

and also in condensing service for steam, high boiling organic limited water, they have not been limited to this situation.

vapors, petroleum still vapors, gasoline, ammonia, etc. In In many instances they are more economical than cooling

general, the economics of application favors service allowing tower systems and have been successfully applied in combi-

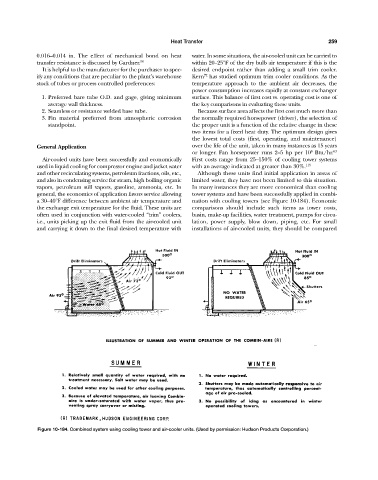

a 30–40°F difference between ambient air temperature and nation with cooling towers (see Figure 10-184). Economic

the exchange exit temperature for the fluid. These units are comparisons should include such items as tower costs,

often used in conjunction with water-cooled “trim” coolers, basin, make-up facilities, water treatment, pumps for circu-

i.e., units picking up the exit fluid from the air-cooled unit lation, power supply, blow down, piping, etc. For small

and carrying it down to the final desired temperature with installations of air-cooled units, they should be compared

Figure 10-184. Combined system using cooling tower and air-cooler units. (Used by permission: Hudson Products Corporation.)