Page 391 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 391

66131_Ludwig_CH11A 5/30/2001 4:50 PM Page 348

348 Applied Process Design for Chemical and Petrochemical Plants

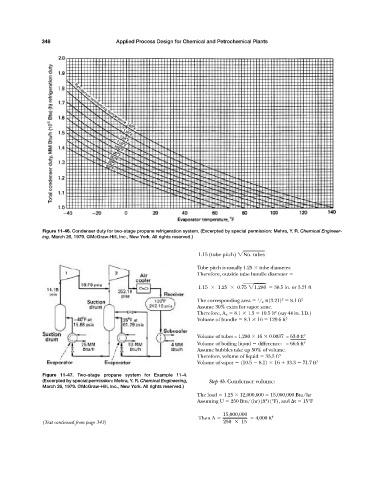

Figure 11-46. Condenser duty for two-stage propane refrigeration system. (Excerpted by special permission: Mehra, Y. R. Chemical Engineer-

ing, March 26, 1979. ©McGraw-Hill, Inc., New York. All rights reserved.)

1.15 1tube pitch2 2No. tubes

Tube pitch is usually 1.25 tube diameter.

Therefore, outside tube bundle diameter

1.15 1.25 0.75 21,280 38.5 in. or 3.21 ft

The corresponding area / 4

(3.21) 8.1 ft 2

2

1

Assume 30% extra for vapor zone.

2

Therefore, A E 8.1 1.3 10.5 ft (say 44 in. I.D.)

Volume of bundle 8.1 16 129.6 ft 3

Volume of tubes = 1,280 16 0.0037 = 63.0 ft 3

Volume of boiling liquid difference: = 66.6 ft 3

Assume bubbles take up 50% of volume.

Therefore, volume of liquid 33.3 ft 3

Volume of vapor (10.5 8.1) 16 33.3 71.7 ft 3

Figure 11-47. Two-stage propane system for Example 11-4.

(Excerpted by special permission: Mehra, Y. R. Chemical Engineering, Step 4b. Condenser volume:

March 26, 1979. ©McGraw-Hill, Inc., New York. All rights reserved.)

The load 1.25 12,000,000 15,000,000 Btu/hr

2

Assuming U 250 Btu/(hr)(ft )(°F), and t 15°F

15,000,000

Then A 4,000 ft 2

(Text continued from page 343) 250 15