Page 247 - Applied Photovoltaics

P. 247

permanent magnet

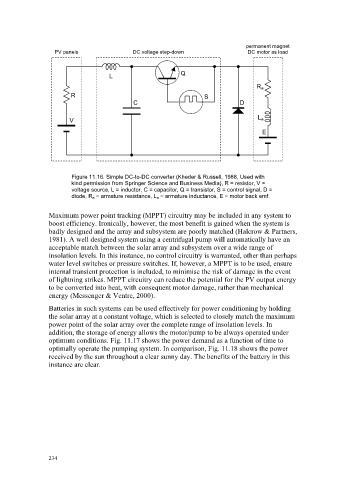

PV panels DC voltage step-down DC motor as load

Q

L

R a

R S

C D

V L a

E

Figure 11.16. Simple DC-to-DC converter (Kheder & Russell, 1988, Used with

kind permission from Springer Science and Business Media), R = resistor, V =

voltage source, L = inductor, C = capacitor, Q = transistor, S = control signal, D =

diode, R a = armature resistance, L a = armature inductance, E = motor back emf.

Maximum power point tracking (MPPT) circuitry may be included in any system to

boost efficiency. Ironically, however, the most benefit is gained when the system is

badly designed and the array and subsystem are poorly matched (Halcrow & Partners,

1981). A well designed system using a centrifugal pump will automatically have an

acceptable match between the solar array and subsystem over a wide range of

insolation levels. In this instance, no control circuitry is warranted, other than perhaps

water level switches or pressure switches. If, however, a MPPT is to be used, ensure

internal transient protection is included, to minimise the risk of damage in the event

of lightning strikes. MPPT circuitry can reduce the potential for the PV output energy

to be converted into heat, with consequent motor damage, rather than mechanical

energy (Messenger & Ventre, 2000).

Batteries in such systems can be used effectively for power conditioning by holding

the solar array at a constant voltage, which is selected to closely match the maximum

power point of the solar array over the complete range of insolation levels. In

addition, the storage of energy allows the motor/pump to be always operated under

optimum conditions. Fig. 11.17 shows the power demand as a function of time to

optimally operate the pumping system. In comparison, Fig. 11.18 shows the power

received by the sun throughout a clear sunny day. The benefits of the battery in this

instance are clear.

234