Page 240 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 240

21 2 Applied Process Design for Chemical and Petrochemical Plants

through V-belts or gears. The pump manufacturer should

know the preferred type of drive. If the manufacturer is to Water 0 Vertical Pumps

furnish the driver, the data on the specification sheet Flow

under Driver should be completed as far as applicable. If

a gas or gasoline engine is to be used, the type of fuel and

its condition must be stated. Engine cooling water (if air d=Bd/3

not used) must be specified.

Sump Design for Vertical Lift

Partition

(see

The proper design of sumps for the use of vertical lift > Ref. [17])

pumps or horizontal pumps taking suction from a sump

is important to good suction conditions at the pump [2,

3, 141.

pump installations. (For more details, refer to Reference -0

The arrangement and dimensions indicated in Figure

3-62 or Figure 3-63 are satisfactory for single or multiple

[17]). A few key points in sump-pump relationships for

good non-vortexing operation are:

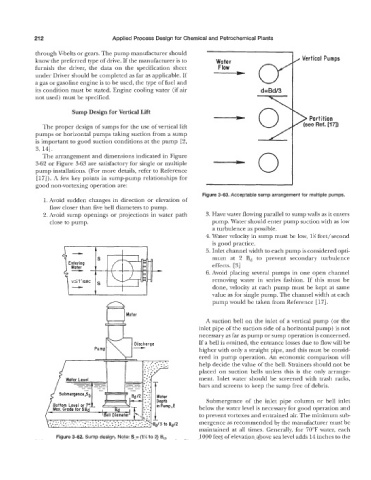

Figure 3-63. Acceptable sump arrangement for multiple pumps.

1. Avoid sudden changes in direction or elevation of

flow closer than five bell diameters to pump.

2. Avoid sump openings or projections in water path 3. Have water flowing parallel to sump walls as it enters

close to pump. pump. Water should enter pump suction with as low

a turbulence as possible.

4. Water velocity in sump must be low, 1% feet/second

is good practice.

5. Inlet channel width to each pump is considered opti-

mum at 2 Bd to prevent secondary turbulence

effects. [3]

6. Avoid placing several pumps in one open channel

removing water in series fashion. If this must be

a value as for single pump. The channel width at each

done, velocity at each pump must be kept at same

pump would be taken from Reference [ 1’71.

Motor

A suction bell on the inlet of a vertical pump (or the

inlet pipe of the suction side of a horizontal pump) is not

necessary as far as pump or sump operation is concerned.

If a bell is omitted, the entrance losses due to flow will be

higher with only a straight pipe, and this must be consid-

ered in pump operation. An economic comparison will

help decide the value of the bell. Strainers should not be

placed on suction bells unless this is the only arrange-

ment. Inlet water should be screened with trash racks,

bars and screens to keep the sump free of debris.

Submergence of the inlet pipe column or bell inlet

below the water level is necessary for good operation and

to prevent vortexes and entrained air. The minimum sub-

mergence as recommended by the manufacturer must be

maintained at all times. Generally, for 70°F water, each

Figure 3-62. Sump design. Note: S = (1% to 2) Bd. 1000 feet of elevation above sea level adds 14 inches to the