Page 244 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 244

21 6 Applied Process Design for Chemical and Petrochemical Plants

I

L‘ U

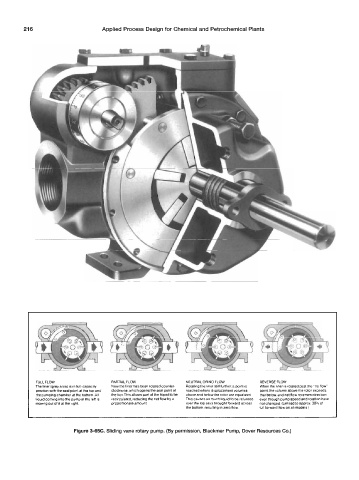

FULL Row PARTIAL FLOW NEUTRAL OR NO FLOW REVERSE FLOW

no

the

The liner (grey area) is in lull-capacity Now the liner has been rotated counler- Rotating the liner slill further a point IS When the liner IS rotated @?+I How”

posilion with the seal point a1 the top and clockwise which opens the seal point at reached where displacement volumes point the uolume above the rotor exceeds

the pumping chamber at the bottom All the lop This allows cart of the lwid to be above and below the rotor are equalized that below. and net Row reverses direction

Iiquld coming into the pump et me lei3 is recirculated. reducing the net flow by a This causes as much lauid to be returned even though pump speed and rotatton have

movtng out of it a1 the rtght propomonale amount over the top as is brought forward across not changed (Limited to approx 30% of

the bottom resulting in zero flow full forward flow on all models )

I

Figure 3-65C. Sliding vane rotary pump. (By permission, Blackmer Pump, Dover Resources Co.)