Page 246 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 246

21 8 Applied Process Design for Chemical and Petrochemical Plants

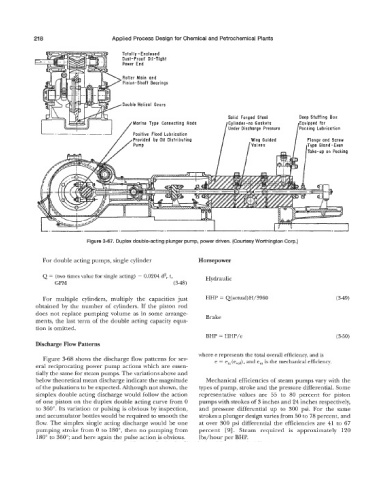

Totally -Enclosed

Dust-Proof Oil-Tight

Roller Main and

Pinion-Shaft Bearings

Double Helical Gears

Solid Forged Steel Deep Stuffing Box

Marine Type Connecting Rods Cylinder-no Gaskets

Under Discharge Pressure Packing Lubrication

Positive Flood Lubrication

Provided by Oil Distributing Flange and Screw

Type Gland-Even

Take-up on Packing

Figure 3-67. Duplex double-acting plunger pump, power driven. (Courtesy Worthington Corp.)

For double acting pumps, single cylinder Horsepower

Q = (two times value for single acting) - 0.0204 dzr t, Hydraulic

GPM (3-48)

For multiple cylinders, multiply the capacities just HHP = Q(actual)H/3960 (3-49)

obtained by the number of cylinders. If the piston rod

does not replace pumping volume as in some arrange- Brake

ments, the last term of the double acting capacity equa-

tion is omitted.

BHP = HHP/e (3-50)

Discharge Flow Patterns

where e represents the total overall efficiency, and is

Figure 3-68 shows the discharge flow patterns for sev- e = em(evol), and e, is the mechanical efficiency.

eral reciprocating power pump actions which are essen-

tially the same for steam pumps. The variations above and

below theoretical mean discharge indicate the magnitude Mechanical efficiencies of steam pumps vary with the

of the pulsations to be expected. Although not shown, the types of pump, stroke and the pressure differential. Some

simplex double acting discharge would follow the action representative values are 55 to 80 percent for piston

of one piston on the duplex double acting curve from 0 pumps with strokes of 3 inches and 24 inches respectively,

to 360". Its variation or pulsing is obvious by inspection, and pressure differential up to 300 psi. For the same

and accumulator bottles would be required to smooth the strokes a plunger design varies from 50 to 78 percent, and

flow. The simplex single acting discharge would be one at over 300 psi differential the efficiencies are 41 to 67

pumping stroke from 0 to 180", then no pumping from percent [9]. Steam required is approximately 120

180" to 360"; and here again the pulse action is obvious. lbs/hour per BHP.