Page 242 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 242

21 4 Applied Process Design for Chemical and Petrochemical Plants

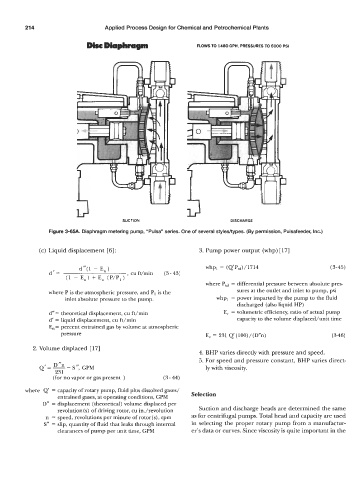

DicrcDiaphny(m FLOWS TO 1480 GPH, PRESSURES TO 5000 PSI

DISCHARGE

Figure 3-MA. Diaphragm metering pump, “Pulsa” series. One of several styleshypes. (By permission, Pulsafeeder, Inc.)

(c) Liquid displacement [6] : 3. Pump power output (whp) [ 171

d”(1 - E, ) whpl = ( Q’Ptd) /1714 (3-45)

d’= , cu ft/min (3- 43)

(1 - E,) + E” (P/P,)

where Ptd = differential pressure between absolute pres-

where P is the.atmospheric pressure, and PI is the sures at the outlet and inlet to pump, psi

inlet absolute pressure to the pump. whpl = power imparted by the pump to the fluid

discharged (also liquid HP)

d“ = theoretical displacement, cu ft/min E, = volumetric efficiency, ratio of actual pump

d’ = liquid displacement, cu ft/min capacity to the volume displaced/unit time

E, = percent entrained gas by volume at atmospheric

pressure E, = 231 Q’(lOO)/(D”n) (3-46)

2. Volume displaced [ 171

4. BHP varies directly with pressure and speed.

5. For speed and pressure constant, BHP varies direct-

Q’=-- ”n S ”, GPM ly with viscosity.

231

(for no vapor or gas present ) (3- 44)

where Q’ = capacity of rotary pump, fluid plus dissolved gases/

entrained gases, at operating conditions, GPM Selection

D” = displacement (theoretical) volume displaced per

revolution(s) of driving rotor, cu in./revolution Suction and discharge heads are determined the same

n = speed, revolutions per minute of rotor(s), rpm as for centrifugal pumps. Total head and capacity are used

S” = slip, quantity of fluid that leaks through internal in selecting the proper rotary pump from a manufactur-

clearances of pump per unit time, GPM er’s data or curves. Since viscosity is quite important in the