Page 71 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 71

Fluid Flow 57

T 7

4 i

I--64 c---B---l

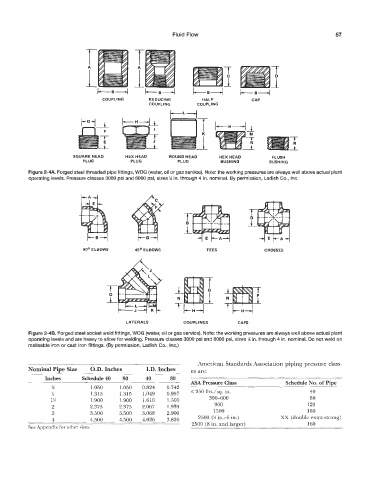

COUPLING RE DUCl NG HALF CAP

COUPLING COUPLING

SQUARE HEAD HEX HEAD ROUND HEAD HEX HEAD FLUSH

PLUG PLUG PLUG BUSHING BUSHING

Figure 2-4A. Forged steed threaded pipe fittings, WOG (water, oil or gas service). Note: the working pressures are always well above actual plant

operaUing levels. Pressure classes 3000 psi and 6000 psi, sizes % in. through 4 in. nominal. By permission, Ladish CO., Inc.

P C

90' ELBOWS 450 E LBOWS TEES GROSSES

T

1 -f-

LATERALS COUPLINGS CAPS

Figure 2-48. Forged steel socket weld fittings, WOG (water, oil or gas service). Note: the working pressures are always well above actual plant

operating levels and are heavy to allow for welding. Pressure classes 3000 psi and 6000 psi, sizes % in. through 4 in. nominal. Do not weld on

malleable iron or cast iron fittings. (By permission, Ladish Go., lnc.)

American Standards Association piping pressure class-

Nominal Pipe Size .D. Inches I.D. Inches es are:

Inches Schedule40 80 40 80 __

MA Pressure Class ~ c No. of ~Pipe e ~ ~ ~

% 1.050 1.050 0.824 0.742

1 1.313 1.315 1.049 0.957 I250 lbs./sq. in. 40

1% 1 .900 1.900 1.610 1.500 300-600 80

2 2.375 '2.375 2.067 1.939 900 120

3 3.500 3.500 3.068 2.900 1500 160

2500 (X in.4 in.)

_ 4 _ - ~ 4.500 4.500 4.026 3.826 2500 (8 in. and larger) XX (double extra strong)

160

See Appendix for other sizes. ____.