Page 247 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 247

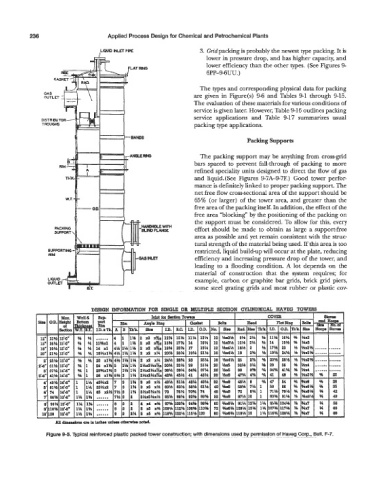

236 Applied Process Design for Chemical and Petrochemical Plants

LlWlD Nrn PIPE 3. Grid packing is probably the newest type packing. It is

lower in pressure drop, and has higher capacity, and

lower efficiency than the other types. (See Figures 9-

LAT 'RlNG

6PP-9-6UU.)

The types and corresponding physical data for packing

are given in Figure(s) 9-6 and Tables 9-1 through 9-15.

The evaluation of these materials for various conditions of

service is given later. However, Table 9-16 outlines packing

service applications and Table 9-17 summarizes usual

packing type applications.

F=l -BANDS Packing Supports

ANGLEWNC The packing support may be anything from cross-grid

bars spaced to prevent fall-through of packing to more

RIM

refined speciality units designed to direct the flow of gas

and liquid. (See Figures 9-7A-9-7F.) Good tower perfor-

manceis definitely linked to proper packing support. The

net free flow cross-sectional area of the support should be

65% (or larger) of the tower area, and greater than the

free area of the packing itself. In addition, the effect of the

free area "blocking" by the positioning of the packing on

the support must be considered. To allow for this, every

effort should be made to obtain as large a support-free

area as possible and yet remain consistent with the struc-

tural strength of the material being used. If this area is too

restricted, liquid build-up will occur at the plate, reducing

efficiency and increasing pressure drop of the tower, and

leading to a flooding condition. A lot depends on the

material of construction that the system requires; for

example, carbon or graphite bar grids, brick grid piers,

some steel grating grids and most rubber or plastic cov-

Maz. Wd6 sup Joint for s.ctbn Toann

Size O.D. Height BotIom I *b Rlns I -Let I

cknemsE'-

of

-

-

- Section eT.1B.T. 1.D.xTk. A IB hh'k.1 Sire I ID. I B.C. 1 ID. l0.D. INo.

-

-

-

12' 12% 154L

15" 15% 17%

18" 18% 20% 19%

- 20% 23%

20"

2 24% 26%

2'4" 30% 33 %

36% 39'k

9'

- 42% 45H

3'4"

4 48% 51H 48% 48%

80% 63% 58% 61%

5 73 76% 70% 74 46

6

- -

-

85% 89% 82% 86%

7

8 87% 100% 94% 98%

- 1% 1% ...... 9 8 2 5 x5 XH 108% 112% 108% 110% 72

9 110% 12'4'

- -

118% 12241 115% 120

10 120 12'4"

1% 1% ...... 9 a 2% 5 x5 .%

u1dlmeadonrosininch..~as othemimnoled.

Figure 9-5. Typical reinforced plastic packed tower construction; with dimensions used by permission of Havsg Corp., Bull. F-7.