Page 257 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 257

246 Applied Process Design for Chemical and Petrochemical Plants

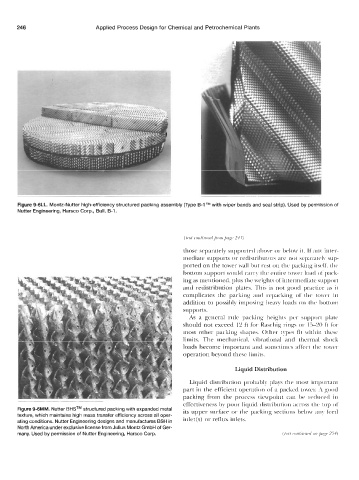

Figure 9-6LL. Montz-Nutter high-efficiency structured packing assembly (Type B-1 TM with wiper bands and seal strip). Used by permission of

Nutter Engineering, Harsco Corp., Bull. 8-1.

those separately supported above or below it. If any inter-

mediate supports or redistributors are not separately sup-

ported on the tower wall but rest on the packing itself, the

bottom support would carry the entire tower load of pack-

ing as mentioned, plus the weights of intermediate support

and redistribution plates. This is riot good practice as it

complicates the packing arid repacking of the tower in

addition to possibly imposing heaky loads on the bottom

supports.

As a general rule packing heights per support plate

should not exceed 12 ft for Raschig rings or 15-20 ft for

most other packing shapes. Other types fit within these

limits. The mechanical, vibrational and thermal shock

loads become important and sometimes affect the tower

operation beyond these limits.

Liquid Distribution

Liquid distribution probably plays the most important

part in the efficient operation of a packed tower. A good

packing from the process viewpoint can be reduced in

effectiveness by poor liquid distribution across the top of

Figure 9-6MM. Nutter BHSTM structured packing with expanded metal its upper surface or the packing sections below any feed

texture, which maintains high mass transfer efficiency across all oper-

ating conditions. Nutter Engineering designs and manufactures BSH in inlet(s) or reflux inlets.

North America under exclusive license from Julius Montz GmbH of Ger-

many. Used by permission of Nutter Engineering, Harsco Corp.