Page 259 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 259

248 Applied Process Design for Chemical and Petrochemical Plants

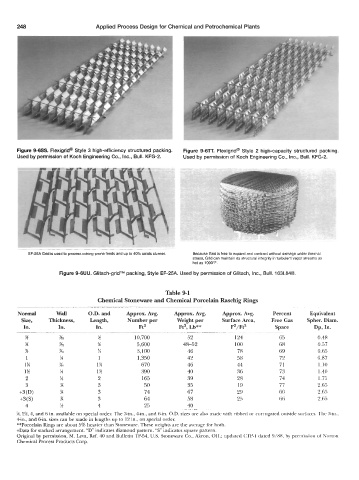

Figure 9-6SS. Flexigrid@' Style 3 high-efficiency structured packing. Figure 9-6TT. Flexigrid@ Style 2 high-capacity structured packing.

Used by permission of Koch Engineering Co., Inc., Bull. KFG-2. Used by permission of Koch Engineering Co., Inc., Bull. KFG-2.

EF-25A Grid is used to process coking-prone feeds and up to 40% solids slurries Because Grid is free to expand and contract without damage under thermal

stress, Grid can maintain its structural integrity in turbulent vapor streams as

hot as 1000°F.

Figure 9-6UU. Glitsch-gridTM packing, Style EF-25A. Used by permission of Glitsch, Inc., Bull. 163L84B.

Table 9-1

Chemical Stoneware and Chemical Porcelain Raschig Rings

__ - ~~

Normal Wall O.D. and Approx. Avg. Approx. Avg. Approx. Avg. Percent Equivalent

Size, Thickness, Length, Number per Weight per Surface Area, Free Gas Spher. Dim.

In. In. In. Ft3 Ft3, Lb** F2/Ft3 Space Dp, In.

% X? w 10,700 52 124 65 0.48

M %e ?k 5,600 48-52 100 68 0.57

w MZ % 3,100 46 78 69 0.65

1 M 1 1,350 42 58 72 0.87

1% XF' 1% 670 46 44 71 1.10

1% !4 1% 390 40 36 73 1.40

2 !4 2 165 39 28 74 1.75

3 :x 3 50 35 19 77 2.65

+3(D) M 3 74 67 29 60 2.65

+3@) M 3 64 58 25 66 2.65

4 w 4 25 40

~~~

~

~

~

~

~~

~~ ~ ~ ~ ~ ~~ ~~~___~____~ ~ ~~ ~~~ ~~~ ~~~_____~

~

~

M, 2%, 4, and 6 in. available on special order. The 3-in., 4in., and &in. O.D. sizes are also made with ribbed or corrugated outside surfaces. The %in.,

4in., and Gin. sizes can be made in lengths up to 12 in., on special order.

**Porcelain Rings are about 5% heavier than Stoneware. These weight3 are the average for both.

+Data for stacked arrangement. "D" indicates diamond pattern. "S" indicates square pattern.

Original by permission, M. Leva, Ref. 40 and Bulletin TP-54, US. Stoneware Co., Akron, OH.; updated CTP-1 dated 9/88, by permission of Norton

Chemical Process Products Corp.