Page 268 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 268

Packed Towers 257

7'- 42'0.0.

Sections 11

Removable

c. w.

Bar

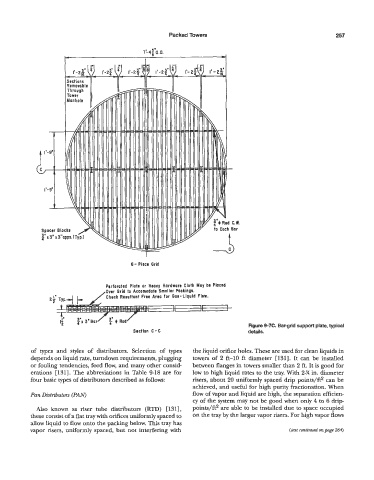

6- Piece Grid

Perforated Plate or Heavy Hardware Cloth May be Placed

Over Grid to Accomodate Smaller Packings.

I'

2P

Figure 9-7C. Bar-grid support plate, typical

Section C-C details.

of types and styles of distributors. Selection of types the liquid orifice holes. These are used for clean liquids in

depends on liquid rate, turndown requirements, plugging towers of 2 ft-10 ft diameter [131]. It can be installed

or fouling tendencies, feed flow, and many other consid- between flanges in towers smaller than 2 ft. It is good for

erations [131]. The abbreviations in Table 9-18 are for low to high liquid rates to the tray. With 24 in. diameter

four basic types of distributors described as follows: risers, about 20 uniformly spaced drip points/ft* can be

achieved, and useful for high purity fractionation. When

Pan Distributors (PAhr) flow of vapor and liquid are high, the separation efficien-

cy of the system may not be good when only 4 to 6 drip-

Also known as riser tube distributors (RTD) [131], points/ft* are able to be installed due to space occupied

these consist of a flat tray with orifices uniformly spaced to on the tray by the larger vapor risers. For high vapor flows

allow liquid to flow onto the packing below. This tray has

vapor risers, uniformly spaced, but not interfering with (lext continued on page 264)