Page 272 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 272

T

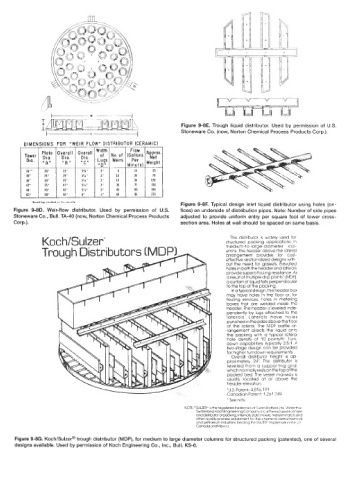

i Figure 9-8E. Trough liquid distributor. Used by permission of U.S.

Stoneware Co. (now, Norton Chemical Process Products Corp.).

Width No of Flow

Plate Overoll Overall

of

‘Er !:; !:,, !;,; Lugs Weirs Per Ap~perpx.

II D II Minute) We’gh’.

24“’ 20” 23” 5%” 3” 8 16 55

30“ 2v 29 5%” 3” 18 36 70

36’ 30” 35“ 51%’’ 3” 18 36 120

42” 35,‘ 41 ’ 5%” 3” 36 72 150

48” 40“ 4w 5w 3” 40 80 190

60” 50” 58” 6’ $3 48 96 270

Figure 9-8F. Typical design inlet liquid distributor using holes (ori-

fices) on underside of distribution pipes. Note: Number of side pipes

adjusted to provide uniform entry per square foot of tower cross-

section area. Holes at wall should be spaced on same basis.

This distributor is widely used for

Koch/Sulzer” structured packing applications in

medium-to-large-diameter col-

umns. The header above the lateral

arrangement provides for cost-

effective sectionalized designs with-

out the need for gaskets. Elevated

holes in both the header and laterals

provide superb fouling resist0nce.h

a resultof multipledrip points‘[MDP).

a curtain of liquid falls perpendicular

to the top of the packing.

In a typical design, the header box

may have holes in the floor or, for

fouling services, holes in metering

boxes that are welded inside the

header The header is leveled inde-

pendently by lugs attached to the

laterals Laterals have holes

punched in the sides above the floor

of the lateral. The MDP baffle ar-

rangement directs the liquid onto

the packing with a typical lateral

hole densiw of 10 points/ftz Turn-

down capabilities. typically 2.5:l. A

two-stage design can be provided

for higher turndown requirements.

Overall distributor height is ap-

proximately 24‘: The distributor is

leveled from a supporting grid.

which normallyrestson thetopofthe

packed bed. The vessel manwoy is

usually located at or above the

header elevation.

*US Patent: 4,816.191

Canadian Patent 1.261.249

“See note

NOTE “SULZER” is the registered trademark of Sulzer Brothers Lid, Winterthur

Swrtrerland Koch EnaineerinaCornnanv lnc istheexclime licensee

CanadoandMexico

Figure 9-8G. Koch/Sulzet@ trough distributor (MDP), for medium to large diameter columns for structured packing (patented), one of several

designs available. Used by permission of Koch Engineering Co., Inc., Bull. KS-6.