Page 269 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 269

4

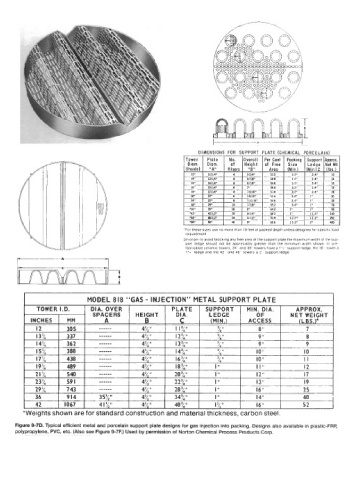

DIMENSIONS FOR SUPPORT PLATE (CHEMICAL PORCELAIN)

a

'For these sizes use no more than 10 feet of packed depth unless designed for specific load

requirement

$In order to avoid blocking any free area of the Support plate the maximum width of the sup-

port ledge should not be appreciably greater than the minimum width shown In pre-

fabricated ceramic towers, 24" and 30" towers have a 1 Y support ledge. the 36 ' tower a

13&' ledge and the 42" and 48" towers a 2" support ledge

I I

MODEL 818 "GAS - INJECTION" METAL SUPPORT PLATE

NET WEIGHT

*Weights shown are for standard construction and material thickness, carbon steel.

Figure 9-7D. Typical efficient metal and porcelain support plate designs for gas injection into packing. Designs also available in plastic-FRP,

polypropylene, PVC, etc. (Also see Figure 9-7F.) Used by permission of Norton Chemical Process Products Corp.