Page 341 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 341

330 Applied Process Design for Chemical and Petrochemical Plants

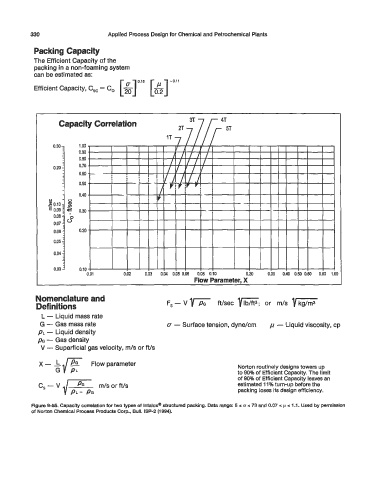

Packing Capacity

The Efficient Capacity of the

packing in a non-foaming system

can be estimated as:

Efficient Capacity, C,, = C, [&]O’l* [&] -0.11

Flow Parameter, X

Nomenclature and

Definitions

L - Liquid mass rate

G - Gas mass rate u - Surface tension, dyne/cm ,u - Liquid viscosity, cp

pL - Liquid density

PO - Gas density

V - Superficial gas velocity, m/s or ft/s

x - LP parameter Norton routinely designs towers up

FIOW

G PL to 90% of Efficient Capacity. The limit

of 90% of Efficient Capacity leaves an

C, - v ,/T m/s or ftls estimated 11% turn-up before the

PL- PO packing loses its design efficiency.

Figure 9-55. Capaclty correlation for two types of Intarox@ shuctumd packing. Data range: 5 a u I 73 and 0.07 s p s 1 .l. Used by permission

of Norton Chemical Process Products Corp., Bull. ISP-2 (1994).