Page 57 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 57

46 Applied Process Design for Chemical and Petrochemical Plants

CI = relative volatility of light to heavy components

y* = equilibrium value of xi

CONDENSER

The condensed vapor is removed as fast as it is formed.

RECEIVER The results of either relation allow the plotting of an

instantaneous vapor composition for given percents of

material taken overhead.

The outline of Teller [70, 1331 suggests using the dif-

ferential form above. Vapor is assumed to be in equilibri-

t! molslhr. =I G, Reflux um with liquid.

1. Calculate or obtain an x-y equilibrium diagram for

+--- Column equivolent the light component.

COLUMN to NTheoretlcal

plates 2. Select values of q and read equilibrium values of yi

{Not u& when only slmple from Step 1 above.

dmerentid dlslillath)

3. Calculate values of 1/ (yi - xi) and tabulate.

4. Plot curve of l/(yi - q) versus xi; see Figure 838,

graphical integration by Simpson’s rule.

5. From the plot of Step 4, determine the area under

the curve from initial bottoms concentration of xio

mol fraction at beginning of distillation down to the

final lower concentration of xi1 in bottoms.

6. The area from Step 5 represents

KETTLE b9 In W/Wi or In Wil/Wio, or (BT,/BT)

Residue or Bottoms

where Wil = the final kettle/still pot content, mols

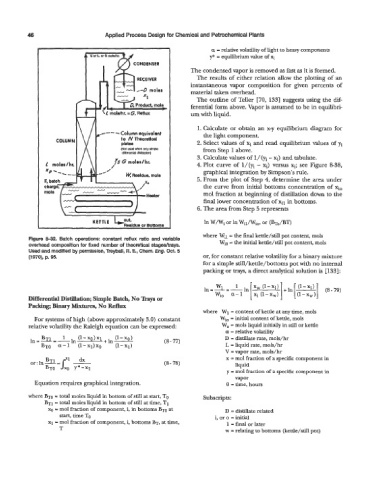

Figure 8-32. Batch operations: constant reflux ratio and variable Wio = the initial kettle/still pot content, mols

overhead composition for fixed number of theoretical stagedtrays.

Used and modified by permission, Treyball, R. E., Chem. Eng. Oct. 5

(1 970), p. 95. or, for constant relative volatility for a binary mixture

for a simple still/kettle/bottoms pot with no internal

packing or trays, a direct analytical solution is [ 1331 :

Differential Distillation; Simple Batch, No Trays or

Packing; Binary Mixtures, No Reflux

where W1 = content of kettle at any time, mols

For systems of high (above approximately 3.0) constant Wio = initial content of kettle, mols

relative volatility the Raleigh equation can be expressed: W,, = mols liquid initially in still or kettle

a = relative volatility

In=%=- 1 In (1-xo)x1 +In (l-xo) (8- 7’7) D = distillate rate, mols/hr

BTO a-1 (1-Xl)xo (l-xl) L = liquid rate, mols/hr

V = vapor rate, mols/hr

x = mol fraction of a specific component in

or: In - (8 - 78) liquid

=

y = mol fraction of a specific component in

vapor

Equation requires graphical integration. 8 = time, hours

where €3~0 = total moles liquid in bottom of still at start, To Subscripts:

= total moles liquid in bottom of still at time, T1

xo = mol fraction of component, i, in bottoms %O at D = distillate related

start, time To i, or o = initial

XI = mol fraction of component, i, bottoms $, at time, 1 = final or later

T w = relating to bottoms (kettle/still pot)