Page 320 - Applied Process Design for Chemical and Petrochemical Plants Volume I

P. 320

Mixing of Liquids 291

B. Open Turbine: Radial

1. Circulates by radially directed centrifugal force

using turbine blades. Circulation good for tank

extremes; less danger of fluid short circuiting in

tank.

2. Generally limited to a maximum speed, range

may be narrow for some services.

3. Used for fairly high shear and turbulence.

4. Better than axial unit for tanks with cone bottom

of greater than 15" angle, to lift material from

bottom of cone and mix with bulk of liquid.

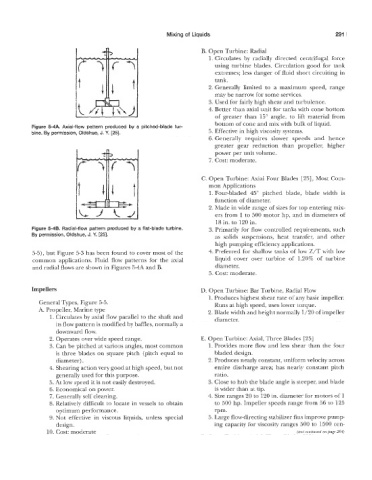

Figure 54% Axial-flow pattern produced by a pitched-blade tur-

bine. By permission, Olldstnue, J. Y. [25]. 5. Effective in high viscosity systems.

6. Generally requires slower speeds and hence

greater gear reduction than propeller, higher

power per unit volume.

7. Cost: moderate.

C. Open Turbine: Axial Four Blades [25], Most Com-

mon Applications

1. Four-bladed 45" pitched blade, blade width is

function of diameter.

2. Made in wide range of sizes for top entering mix-

ers from 1 to 500 motor hp, and in diameters of

18 in. to 120 in.

Figure 5-48. Radiabflotw pattern produced by a flat-blade turbine. 3. Primarily for flow controlled requirements, such

By permission, Oldshuca, J. Y. [25]. as solids suspensions, heat transfer, and other

high pumping efficiency applications.

5-5), but Figure 5-3 has been found to cover most of the 4. Preferred for shallow tanks of low Z/T with low

common applications. Fluid Row patterns for the axial liquid cover over turbine of 1.20% of turbine

and radial flows are shown in Figures 5-4A and B. diameter.

5. Cost: moderate.

D. Open Turbine: Bar Turbine,

1. Produces highest shear rate of any basic impeller.

General Types, Figure 5-5. Runs at high speed, uses lower torque.

A. Propeller, Marine type 2. Blade width and height normally 1/20 of impeller

1. Circulates by axial flow parallel to the shaft and diameter.

its flow pattern is modified by baffles, normally a

downward flow.

2. Operates over wide speed range. E. Open Turbine: Axial, Three

3. Can be pitched at various angles, most common 1. Provides more flow and less shear than the four

is three b'lades on square pitch (pitch equal to bladed design.

diameter). 2. Produces nearly constant, uniform velocity across

4. Shearing action very good at high speed, but not entire discharge area; has nearly constant pitch

generally used for this purpose. ratio.

5. At low speed it is not easily destroyed. 3. Close to hub the blade angle is steeper, and blade

6. Economical on power. is wider than at tip.

7. Generally self cleaning. 4. Size ranges 20 to 120 in. diameter for motors of 1

8. Relatively difficult to locate in vessels to obtain to 500 hp. Impeller speeds range from 56 to 125

optimum performance. rpm.

9. Not effective in viscous liquids, unless special 5. Large flow-directing stabilizer fins improve pump-

design. ing capacity for viscosity ranges 580 to 1500 cen-

10. Cost: moderate (text contanned on page 294)