Page 32 - Assurance of Sterility for Sensitive Combination Products and Materials

P. 32

20 Assurance of sterility for sensitive combination products and materials

Biotech Info Tech

Pharmaceuticals Hardware

Diganostics Genomics Software

Research/info Bioinformatics Communications

Tools Proteomics

Industrial

Biosensors

Bioelctronics Biochips Nanodevices

Microfluidics Nanosensors

Nanobiotech Nanoelectronics

Drug delivery

Nano tech

Electrical

Structural

Biomedical

Energy & environment

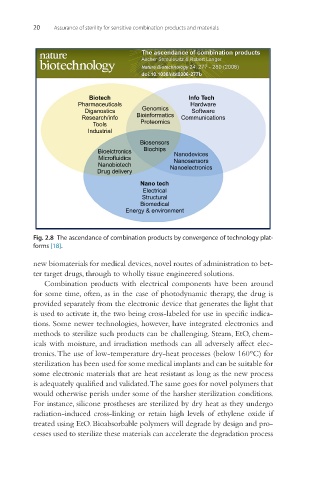

Fig. 2.8 The ascendance of combination products by convergence of technology plat-

forms [18].

new biomaterials for medical devices, novel routes of administration to bet-

ter target drugs, through to wholly tissue engineered solutions.

Combination products with electrical components have been around

for some time, often, as in the case of photodynamic therapy, the drug is

provided separately from the electronic device that generates the light that

is used to activate it, the two being cross-labeled for use in specific indica-

tions. Some newer technologies, however, have integrated electronics and

methods to sterilize such products can be challenging. Steam, EtO, chem-

icals with moisture, and irradiation methods can all adversely affect elec-

tronics. The use of low-temperature dry-heat processes (below 160°C) for

sterilization has been used for some medical implants and can be suitable for

some electronic materials that are heat resistant as long as the new process

is adequately qualified and validated. The same goes for novel polymers that

would otherwise perish under some of the harsher sterilization conditions.

For instance, silicone prostheses are sterilized by dry heat as they undergo

radiation-induced cross-linking or retain high levels of ethylene oxide if

treated using EtO. Bioabsorbable polymers will degrade by design and pro-

cesses used to sterilize these materials can accelerate the degradation process