Page 74 - Assurance of Sterility for Sensitive Combination Products and Materials

P. 74

60 Assurance of sterility for sensitive combination products and materials

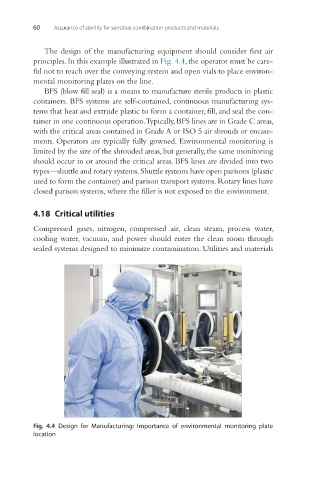

The design of the manufacturing equipment should consider first air

principles. In this example illustrated in Fig. 4.4, the operator must be care-

ful not to reach over the conveying system and open vials to place environ-

mental monitoring plates on the line.

BFS (blow fill seal) is a means to manufacture sterile products in plastic

containers. BFS systems are self-contained, continuous manufacturing sys-

tems that heat and extrude plastic to form a container, fill, and seal the con-

tainer in one continuous operation. Typically, BFS lines are in Grade C areas,

with the critical areas contained in Grade A or ISO 5 air shrouds or encase-

ments. Operators are typically fully gowned. Environmental monitoring is

limited by the size of the shrouded areas, but generally, the same monitoring

should occur in or around the critical areas. BFS lines are divided into two

types—shuttle and rotary systems. Shuttle systems have open parisons (plastic

used to form the container) and parison transport systems. Rotary lines have

closed parison systems, where the filler is not exposed to the environment.

4.18 Critical utilities

Compressed gases, nitrogen, compressed air, clean steam, process water,

cooling water, vacuum, and power should enter the clean room through

sealed systems designed to minimize contamination. Utilities and materials

Fig. 4.4 Design for Manufacturing: Importance of environmental monitoring plate

location