Page 75 - Assurance of Sterility for Sensitive Combination Products and Materials

P. 75

Aseptic processing 61

transporting utilities should, where possible, be treated to eliminate contam-

ination. Compressed gases, nitrogen, and air should be filtered to remove

microbiological contamination. Electrical power should be uninterrupted.

It is recommended that backup systems be in place to ensure that critical

control operations such as airflow through the HEPA system are not inter-

rupted. Routine monitoring and testing of the utilities and materials should

be performed to confirm the output of the utilities and quality process

materials.

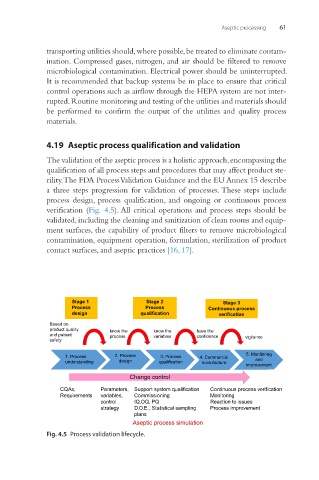

4.19 Aseptic process qualification and validation

The validation of the aseptic process is a holistic approach, encompassing the

qualification of all process steps and procedures that may affect product ste-

rility. The FDA Process Validation Guidance and the EU Annex 15 describe

a three steps progression for validation of processes. These steps include

process design, process qualification, and ongoing or continuous process

verification (Fig. 4.5). All critical operations and process steps should be

validated, including the cleaning and sanitization of clean rooms and equip-

ment surfaces, the capability of product filters to remove microbiological

contamination, equipment operation, formulation, sterilization of product

contact surfaces, and aseptic practices [16, 17].

Stage 1 Stage 2 Stage 3

Process Process Continuous process

design qualification verification

Based on

product quality know the know the have the

and patient process variables confidence vigilance

safety

1. Process 2. Process 3. Process 4. Commercial 5. Monitoring

and

understanding design qualification manufacture improvement

Change control

CQAs, Parameters, Support system qualification Continuous process verification

Requirements variables, Commissioning Monitoring

control IQ,OQ, PQ Reaction to issues

strategy D.O.E., Statistical sampling Process improvement

plans

Aseptic process simulation

Fig. 4.5 Process validation lifecycle.