Page 151 - 05. Subyek Teknik Mesin - Automobile Mechanical and Electrical Systems Automotive Technology Vehicle Maintenance and Repair (Vehicle Maintenance Repr Nv2) by Tom Denton

P. 151

2

Engine systems 135

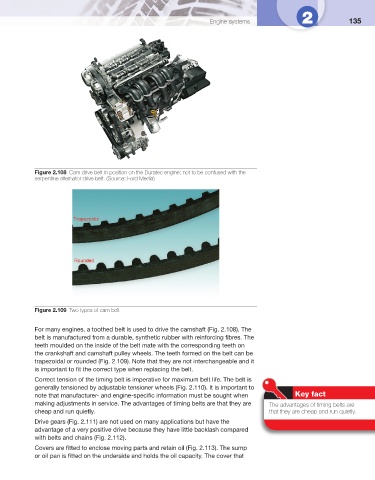

Figure 2.108 Cam drive belt in position on the Duratec engine; not to be confused with the

serpentine alternator drive belt. (Source: Ford Media)

Figure 2.109 Two types of cam belt

For many engines, a toothed belt is used to drive the camshaft ( Fig. 2.108 ). The

belt is manufactured from a durable, synthetic rubber with reinforcing fi bres. The

teeth moulded on the inside of the belt mate with the corresponding teeth on

the crankshaft and camshaft pulley wheels. The teeth formed on the belt can be

trapezoidal or rounded ( Fig. 2.109 ). Note that they are not interchangeable and it

is important to fi t the correct type when replacing the belt.

Correct tension of the timing belt is imperative for maximum belt life. The belt is

generally tensioned by adjustable tensioner wheels ( Fig. 2.110 ). It is important to

note that manufacturer- and engine-specifi c information must be sought when Key fact

making adjustments in service. The advantages of timing belts are that they are The advantages of timing belts are

cheap and run quietly. that they are cheap and run quietly.

Drive gears ( Fig. 2.111 ) are not used on many applications but have the

advantage of a very positive drive because they have little backlash compared

with belts and chains ( Fig. 2.112 ).

Covers are fi tted to enclose moving parts and retain oil ( Fig. 2.113 ). The sump

or oil pan is fi tted on the underside and holds the oil capacity. The cover that