Page 162 - 05. Subyek Teknik Mesin - Automobile Mechanical and Electrical Systems Automotive Technology Vehicle Maintenance and Repair (Vehicle Maintenance Repr Nv2) by Tom Denton

P. 162

2

146 Automobile mechanical and electrical systems

Figure 2.128 Gear pump

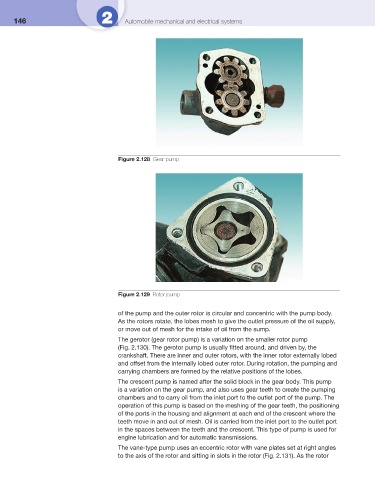

Figure 2.129 Rotor pump

of the pump and the outer rotor is circular and concentric with the pump body.

As the rotors rotate, the lobes mesh to give the outlet pressure of the oil supply,

or move out of mesh for the intake of oil from the sump.

The gerotor (gear rotor pump) is a variation on the smaller rotor pump

( Fig. 2.130 ). The gerotor pump is usually fi tted around, and driven by, the

crankshaft. There are inner and outer rotors, with the inner rotor externally lobed

and offset from the internally lobed outer rotor. During rotation, the pumping and

carrying chambers are formed by the relative positions of the lobes.

The crescent pump is named after the solid block in the gear body. This pump

is a variation on the gear pump, and also uses gear teeth to create the pumping

chambers and to carry oil from the inlet port to the outlet port of the pump. The

operation of this pump is based on the meshing of the gear teeth, the positioning

of the ports in the housing and alignment at each end of the crescent where the

teeth move in and out of mesh. Oil is carried from the inlet port to the outlet port

in the spaces between the teeth and the crescent. This type of pump is used for

engine lubrication and for automatic transmissions.

The vane-type pump uses an eccentric rotor with vane plates set at right angles

to the axis of the rotor and sitting in slots in the rotor ( Fig. 2.131 ). As the rotor