Page 124 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 124

CH AP TER 5 .1 Transmissions and driveline

Fluid flow

Stator

Turbine Impeller

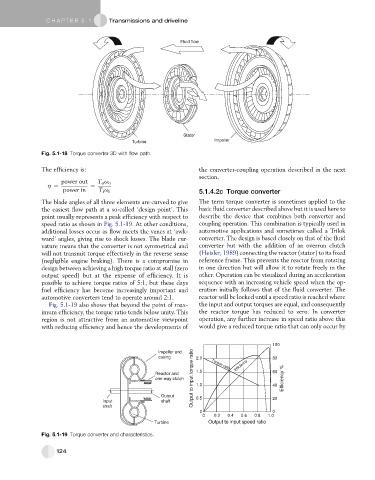

Fig. 5.1-18 Torque converter 3D with flow path.

The efficiency is: the converter-coupling operation described in the next

section.

power out T o u o

h ¼ ¼

power in T i u i 5.1.4.2c Torque converter

The blade angles of all three elements are curved to give The term torque converter is sometimes applied to the

the easiest flow path at a so-called ‘design point’. This basic fluid converter described above but it is used here to

point usually represents a peak efficiency with respect to describe the device that combines both converter and

speed ratio as shown in Fig. 5.1-19. At other conditions, coupling operation. This combination is typically used in

additional losses occur as flow meets the vanes at ‘awk- automotive applications and sometimes called a Trilok

ward’ angles, giving rise to shock losses. The blade cur- converter. The design is based closely on that of the fluid

vature means that the converter is not symmetrical and converter but with the addition of an overrun clutch

will not transmit torque effectively in the reverse sense (Heisler, 1989) connecting the reactor (stator) to its fixed

(negligible engine braking). There is a compromise in reference frame. This prevents the reactor from rotating

design between achieving a high torque ratio at stall (zero in one direction but will allow it to rotate freely in the

output speed) but at the expense of efficiency. It is other. Operation can be visualized during an acceleration

possible to achieve torque ratios of 5:1, but these days sequence with an increasing vehicle speed when the op-

fuel efficiency has become increasingly important and eration initially follows that of the fluid converter. The

automotive converters tend to operate around 2:1. reactor will be locked until a speed ratio is reached where

Fig. 5.1-19 also shows that beyond the point of max- the input and output torques are equal, and consequently

imum efficiency, the torque ratio tends below unity. This the reactor torque has reduced to zero. In converter

region is not attractive from an automotive viewpoint operation, any further increase in speed ratio above this

with reducing efficiency and hence the developments of would give a reduced torque ratio that can only occur by

100

Output to input torque ratio 1.0 40

Impeller and

casing 2.0 Torque ratio 80

Reactor and 1.5 Efficiency 60

one-way clutch Efficiency %

Output 0.5 20

Input shaft

shaft

0 0

0 0.2 0.4 0.6 0.8 1.0

Turbine Output to input speed ratio

Fig. 5.1-19 Torque converter and characteristics.

124