Page 129 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 129

Transmissions and driveline CHAPTER 5.1

Instruments

D/4 S/W

ABS (Test S/W)

sportmode S/W

Engine management Automatic

system transmission pattern selection S/W

control unit

Line Shift Shift Shift Reduction 2-4 brake 2-4 brake Fluid

Lock-up Low clutch

pressure solenoid solenoid solenoid timing timing duty temperature

solenoid timing solenoid

solenoid A B C solenoid solenoid solenoid sensor

Inhibitor switch

Control valve

Select

lever

Turbine sensor Secondary shaft sensor

Vehicle speed sensor

Torque converter Input shaft planetary, Output gear Reduction gear train Parking gear Drive shaft

Clutch,

Engine Oil pump 4 speed gear train Idler gear Final gear and differential Tyre

brake,

gear,

etc.

Transmission assembly

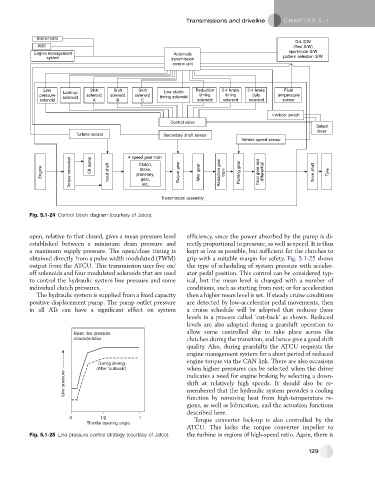

Fig. 5.1-24 Control block diagram (courtesy of Jatco).

open, relative to that closed, gives a mean pressure level efficiency, since the power absorbed by the pump is di-

established between a minimum drain pressure and rectly proportional to pressure, as well as speed. It is thus

a maximum supply pressure. The open/close timing is kept as low as possible, but sufficient for the clutches to

obtained directly from a pulse width modulated (PWM) grip with a suitable margin for safety. Fig. 5.1-25 shows

output from the ATCU. This transmission uses five on/ the type of scheduling of system pressure with acceler-

off solenoids and four modulated solenoids that are used ator pedal position. This control can be considered typ-

to control the hydraulic system line pressure and some ical, but the mean level is changed with a number of

individual clutch pressures. conditions, such as starting from rest; or for acceleration

The hydraulic system is supplied from a fixed capacity then a higher mean level is set. If steady cruise conditions

positive displacement pump. The pump outlet pressure are detected by low-accelerator pedal movements, then

in all ATs can have a significant effect on system a cruise schedule will be adopted that reduces these

levels in a process called ‘cut-back’ as shown. Reduced

levels are also adopted during a gearshift operation to

Basic line pressure allow some controlled slip to take place across the

characteristics clutches during the transition, and hence give a good shift

quality. Also, during gearshifts the ATCU requests the

engine management system for a short period of reduced

engine torque via the CAN link. There are also occasions

During driving

(After ‘cutback’) when higher pressures can be selected when the driver

Line pressure shift at relatively high speeds. It should also be re-

indicates a need for engine braking by selecting a down-

membered that the hydraulic system provides a cooling

function by removing heat from high-temperature re-

gions, as well as lubrication, and the actuation functions

described here.

0 1/2 1 Torque converter lock-up is also controlled by the

Throttle opening angle

ATCU. This locks the torque converter impeller to

Fig. 5.1-25 Line pressure control strategy (courtesy of Jatco). the turbine in regions of high-speed ratio. Again, there is

129