Page 143 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 143

CH AP TER 6 .1 Battery/fuel-cell EV design packages

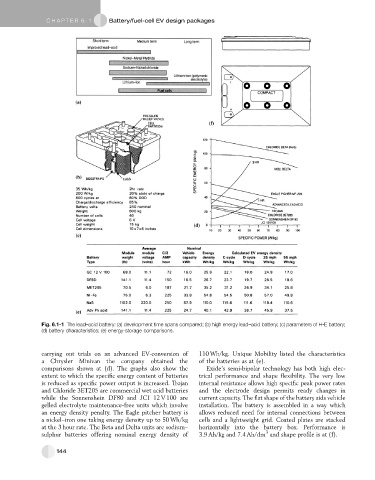

Fig. 6.1-1 The lead–acid battery: (a) development time spans compared; (b) high energy lead–acid battery; (c) parameters of H-E battery;

(d) battery characteristics; (e) energy-storage comparisons.

carrying out trials on an advanced EV-conversion of 110 Wh/kg. Unique Mobility listed the characteristics

a Chrysler Minivan the company obtained the of the batteries as at (e).

comparisons shown at (d). The graphs also show the Exide’s semi-bipolar technology has both high elec-

extent to which the specific energy content of batteries trical performance and shape flexibility. The very low

is reduced as specific power output is increased. Trojan internal resistance allows high specific peak power rates

and Chloride 3ET205 are commercial wet acid batteries and the electrode design permits ready changes in

while the Sonnenshein DF80 and JCI 12 V 100 are current capacity. The flat shape of the battery aids vehicle

gelled electrolyte maintenance-free units which involve installation. The battery is assembled in a way which

an energy density penalty. The Eagle pitcher battery is allows reduced need for internal connections between

a nickel–iron one taking energy density up to 50 Wh/kg cells and a lightweight grid. Coated plates are stacked

at the 3 hour rate. The Beta and Delta units are sodium– horizontally into the battery box. Performance is

3

sulphur batteries offering nominal energy density of 3.9 Ah/kg and 7.4 Ah/dm and shape profile is at (f).

144