Page 148 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 148

Battery/fuel-cell EV design packages CHAPTER 6.1

of five connected in series to give maximum output of current commercial process taking 3 hours. An EC study

1.3 watts (0.6 A at 2.2 V). Some ten modules might be has also shown that mass production of solar cells could

used in a solar panel giving 13 watts output in summer bring substantial benefits and that a £350 million plant

conditions. Power vs voltage and current vs voltage are investment could produce enough panels to produce

shown at (a) for so-called ‘standard’ and ‘typical’ oper- 500 MW annually and cut the generating cost from

2

ating conditions. 100 mW/cm solar intensity, 0 C cell 64 p/kWh to 13p.

temperature at sea level defines the standard conditions

2

against 80 mW/cm and 25 C which represent ‘typical’

conditions at which power output per cell drops to 1 W. 6.1.2.6 Lithium-ion

Temperature coefficients for modules are 0.45% change

in power output per 1 C rise in temperature, relative to A high energy battery receiving considerable attention is

0 C; cell temperatures will be 20 C above ambient at the lithium-ion cell unit, the development of which has

1

2

100 mW/cm incident light intensity. Variation of solar been described by Nissan and Sony engineers who point

energy at 52 north latitude, assuming a clear atmo- out that because of the high cell voltage, relatively few

sphere, is shown at (b). On this basis the smallest one cells are required and better battery management is thus

person car with a speed of 15 mph and a weight of 300 lb obtained. Accurate detection of battery state-of-charge is

2

2

with driver would require 250 W or 50 ft (4.65 m ) possible based on voltage measurement. In the battery

2

2

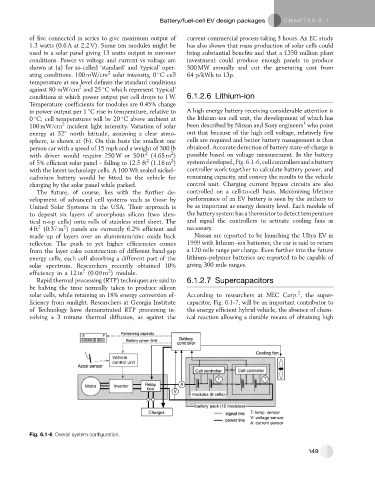

of 5% efficient solar panel – falling to 12.5 ft (1.18 m ) system developed, Fig. 6.1-6, cell controllers and a battery

with the latest technology cells. A 100 Wh sealed nickel– controller work together to calculate battery power, and

cadmium battery would be fitted to the vehicle for remaining capacity, and convey the results to the vehicle

charging by the solar panel while parked. control unit. Charging current bypass circuits are also

The future, of course, lies with the further de- controlled on a cell-to-cell basis. Maximizing lifetime

velopment of advanced cell systems such as those by performance of an EV battery is seen by the authors to

United Solar Systems in the USA. Their approach is be as important as energy density level. Each module of

to deposit six layers of amorphous silicon (two iden- the battery system has a thermistor to detect temperature

tical n-i-p cells) onto rolls of stainless steel sheet. The and signal the controllers to activate cooling fans as

2

2

4ft (0.37 m ) panels are currently 6.2% efficient and necessary.

made up of layers over an aluminium/zinc oxide back Nissan are reported to be launching the Ultra EV in

reflector. The push to yet higher efficiencies comes 1999 with lithium–ion batteries; the car is said to return

from the layer cake construction of different band-gap a 120 mile range per charge. Even further into the future

energy cells, each cell absorbing a different part of the lithium–polymer batteries are reported to be capable of

solar spectrum. Researchers recently obtained 10% giving 300 mile ranges.

2

2

efficiency in a 12 in (0.09 m ) module.

Rapid thermal processing (RTP) techniques are said to 6.1.2.7 Supercapacitors

be halving the time normally taken to produce silicon

2

solar cells, while retaining an 18% energy conversion ef- According to researchers at NEC Corp. , the super-

ficiency from sunlight. Researchers at Georgia Institute capacitor, Fig. 6.1-7, will be an important contributor to

of Technology have demonstrated RTP processing in- the energy efficient hybrid vehicle, the absence of chem-

volving a 3 minute thermal diffusion, as against the ical reaction allowing a durable means of obtaining high

Fig. 6.1-6 Overall system configuration.

149