Page 144 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 144

Battery/fuel-cell EV design packages CHAPTER 6.1

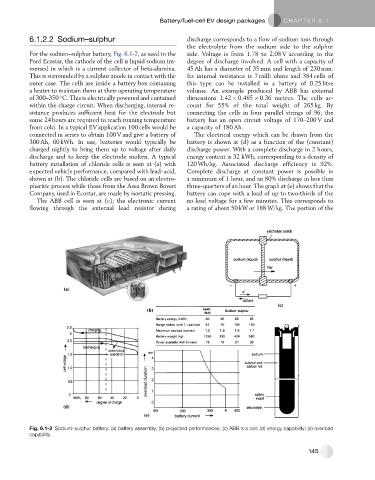

6.1.2.2 Sodium–sulphur discharge corresponds to a flow of sodium ions through

the electrolyte from the sodium side to the sulphur

For the sodium–sulphur battery, Fig. 6.1-2, as used in the side. Voltage is from 1.78 to 2.08 V according to the

Ford Ecostar, the cathode of the cell is liquid sodium im- degree of discharge involved. A cell with a capacity of

mersed in which is a current collector of beta-alumina. 45 Ah has a diameter of 35 mm and length of 230 mm.

This is surrounded by a sulphur anode in contact with the Its internal resistance is 7 milli ohms and 384 cells of

outer case. The cells are inside a battery box containing this type can be installed in a battery of 0.25 litre

a heater to maintain them at their operating temperature volume. An example produced by ABB has external

of 300–350 C. This is electrically powered and contained dimensions 1.42 0.485 0.36 metres. The cells ac-

within the charge circuit. When discharging, internal re- count for 55% of the total weight of 265 kg. By

sistance produces sufficient heat for the electrode but connecting the cells in four parallel strings of 96, the

some 24 hours are required to reach running temperature battery has an open circuit voltage of 170–200 V and

from cold. In a typical EV application 100 cells would be acapacity of 180 Ah.

connected in series to obtain 100 V and give a battery of The electrical energy which can be drawn from the

300 Ah, 60 kWh. In use, batteries would typically be battery is shown at (d) as a function of the (constant)

charged nightly to bring them up to voltage after daily discharge power. With a complete discharge in 2 hours,

discharge and to keep the electrode molten. A typical energy content is 32 kWh, corresponding to a density of

battery installation of chloride cells is seen at (a) with 120 Wh/kg. Associated discharge efficiency is 92%.

expected vehicle performance, compared with lead–acid, Complete discharge at constant power is possible in

shown at (b). The chloride cells are based on an electro- a minimum of 1 hour, and an 80% discharge in less than

pheritic process while those from the Asea Brown Boveri three-quarters of an hour. The graph at (e) shows that the

Company, used in Ecostar, are made by isostatic pressing. battery can cope with a load of up to two-thirds of the

The ABB cell is seen at (c); the electronic current no-load voltage for a few minutes. This corresponds to

flowing through the external load resistor during a rating of about 50 kW or 188 W/kg. The portion of the

Fig. 6.1-2 Sodium–sulphur battery: (a) battery assembly; (b) projected performances; (c) ABB s-s cell; (d) energy capability; (e) overload

capability.

145