Page 149 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 149

CH AP TER 6 .1 Battery/fuel-cell EV design packages

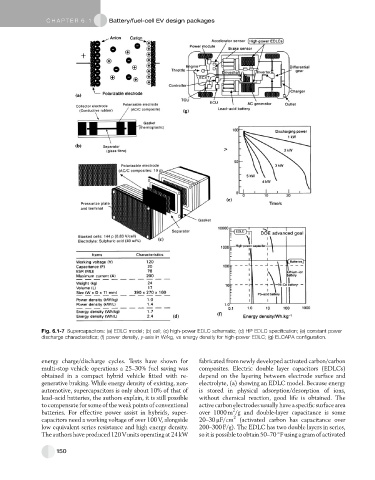

Fig. 6.1-7 Supercapacitors: (a) EDLC model; (b) cell; (c) high-power EDLC schematic; (d) HP EDLC specification; (e) constant power

discharge characteristics; (f) power density, y-axis in W/kg, vs energy density for high-power EDLC; (g) ELCAPA configuration.

energy charge/discharge cycles. Tests have shown for fabricated from newly developed activated carbon/carbon

multi-stop vehicle operations a 25–30% fuel saving was composites. Electric double layer capacitors (EDLCs)

obtained in a compact hybrid vehicle fitted with re- depend on the layering between electrode surface and

generative braking. While energy density of existing, non- electrolyte, (a) showing an EDLC model. Because energy

automotive, supercapacitors is only about 10% of that of is stored in physical adsorption/desorption of ions,

lead–acid batteries, the authors explain, it is still possible without chemical reaction, good life is obtained. The

to compensate for some of the weak points of conventional active carbon electrodesusually have a specificsurface area

2

batteries. For effective power assist in hybrids, super- over 1000 m /g and double-layer capacitance is some

2

capacitors need a working voltage of over 100 V, alongside 20–30 mF/cm (activated carbon has capacitance over

low equivalent series resistance and high energy density. 200–300 F/g). The EDLC has two double layers in series,

The authors have produced 120 Vunits operating at 24 kW so it is possible to obtain 50–70 Fusing a gram of activated

150