Page 157 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 157

CH AP TER 6 .1 Battery/fuel-cell EV design packages

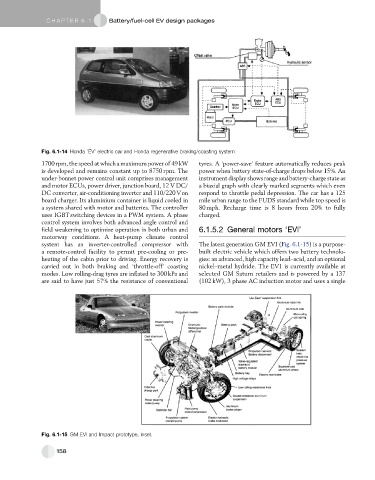

Fig. 6.1-14 Honda ‘EV’ electric car and Honda regenerative braking/coasting system.

1700 rpm, the speed at which a maximum power of 49 kW tyres. A ‘power-save’ feature automatically reduces peak

is developed and remains constant up to 8750 rpm. The power when battery state-of-charge drops below 15%. An

under-bonnet power control unit comprises management instrument display shows range and battery-charge state as

and motor ECUs, power driver, junction board, 12 V DC/ a biaxial graph with clearly marked segments which even

DC converter, air-conditioning inverter and 110/220 Von respond to throttle pedal depression. The car has a 125

board charger. Its aluminium container is liquid cooled in mile urban range to the FUDS standard while top speed is

a system shared with motor and batteries. The controller 80 mph. Recharge time is 8 hours from 20% to fully

uses IGBT switching devices in a PWM system. A phase charged.

control system involves both advanced angle control and

field weakening to optimize operation in both urban and 6.1.5.2 General motors ‘EVl’

motorway conditions. A heat-pump climate control

system has an inverter-controlled compressor with The latest generation GM EVI (Fig. 6.1-15) is a purpose-

a remote-control facility to permit pre-cooling or pre- built electric vehicle which offers two battery technolo-

heating of the cabin prior to driving. Energy recovery is gies: an advanced, high capacity lead–acid, and an optional

carried out in both braking and ‘throttle-off’ coasting nickel–metal hydride. The EV1 is currently available at

modes. Low rolling-drag tyres are inflated to 300 kPa and selected GM Saturn retailers and is powered by a 137

are said to have just 57% the resistance of conventional (102 kW), 3 phase AC induction motor and uses a single

Fig. 6.1-15 GM EVl and Impact prototype, inset.

158