Page 163 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 163

CH AP TER 6 .1 Battery/fuel-cell EV design packages

saloon car achieved 30% gradient ability, 0–50 mph ac- unnecessary acceleration once the vehicle has reached

celeration in less than 20 seconds, 60 mph top speed and running speed in stop–start work; using generously rated

0.25 kWh/mile energy consumption. Gear ratios were motors rather than overspecifying battery capacity–the

15.52 and 10.15:1, and rearward speed was obtained by latter because large batteries cost more, displace payload

electrically reversing the motor; in ‘neutral’ the motor and waste energy providing tractive force required for

was electrically disconnected. their extra weight.

Whereas over a decade ago the rule of thumb applied

6.1.6.3 UK EVA practice for CVS that 1 tonne of batteries plus one of vehicle and one of

payload could be transported at 20 mph over a 20 mile

In its manual of good practice for battery electric vehicles range including 200 stop–starts per charge, now 40/40 to

the Electric Vehicle Association lays down some useful 50/50 mph/miles range is feasible by careful design.

ground rules for conceptual design of road-going electric Belted radial tyres can now be run at 50% above normal

trucks. Exploiting the obvious benefits of EV technology inflation pressures. High voltage series motors of 72 V

is the first consideration. Thus an ultra-low floor walk- and above have working efficiencies of 85–90% over a 3:1

through cab is a real possibility when batteries and speed range and electronic controllers cut peak acceler-

motors can be mounted remotely. Lack of fuelling re- ation currents and avoid resistive losses – to extend

quirement, ease of start-up and getaway–also driving ranges by 15–20% over resistance controllers. A further

simplicity of two-pedal control without gearshifting – all 10% range increase is possible if high frequency con-

these factors lend themselves to operations, such as busy trollers (15 000 Hz) are used–also much lower internal-

city-centre deliveries where a substantial part of the resistance batteries reduce voltage fall-off and the use of

driver’s time is spent in off-loading and order-taking. Any DC/DC converters means that cells do not have to work

aspect of vehicle design which minimizes the driving task so deeply to power auxiliaries, the EVA explain. The

thus maximizes his or her other workload duties. Suc- percentage of GVW allocated to the battery is a key

cessful builders of electric trucks are thus, say the EVA, parameter which should be kept below 35%. Lightweight

specialists in assembling bought-in systems and compo- lead–acid batteries giving 15–25% greater specific ca-

nents. Required expertise is in tailoring a motor/battery/ pacity than the BS 2550 standard traction cell should be

speed-controller package to a given application. Princi- considered, as they also have better discharge charac-

ples to be followed in this process are keeping top speeds teristics, but there is usually a trade-off in equivalent

and motor power as low as possible consistent with percentage life reductions. Separately excited motors

fulfilling the task; using controllers which prevent any and regenerative braking give further bonuses.

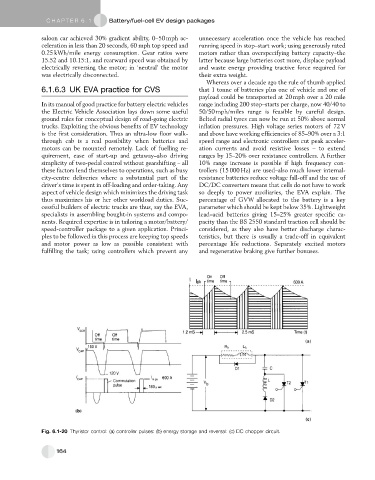

Fig. 6.1-20 Thyristor control: (a) controller pulses: (b) energy storage and reversal: (c) DC chopper circuit.

164