Page 165 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 165

CH AP TER 6 .1 Battery/fuel-cell EV design packages

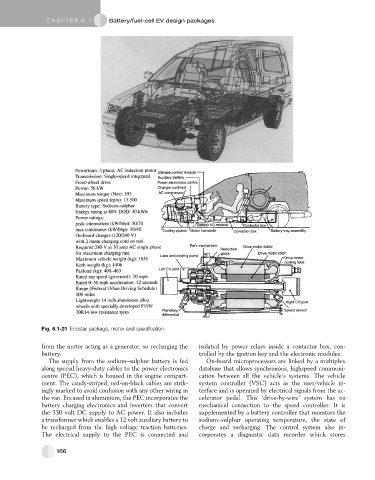

Fig. 6.1-21 Ecostar package, motor and specification.

from the motor acting as a generator, so recharging the isolated by power relays inside a contactor box, con-

battery. trolled by the ignition key and the electronic modules.

The supply from the sodium–sulphur battery is fed On-board microprocessors are linked by a multiplex

along special heavy-duty cables to the power electronics database that allows synchronous, highspeed communi-

centre (PEC), which is housed in the engine compart- cation between all the vehicle’s systems. The vehicle

ment. The candy-striped, red-on-black cables are strik- system controller (VSC) acts as the user/vehicle in-

ingly marked to avoid confusion with any other wiring in terface and is operated by electrical signals from the ac-

the van. Encased in aluminium, the PEC incorporates the celerator pedal. This ‘drive-by-wire’ system has no

battery charging electronics and inverters that convert mechanical connection to the speed controller. It is

the 330 volt DC supply to AC power. It also includes supplemented by a battery controller that monitors the

a transformer which enables a 12 volt auxiliary battery to sodium–sulphur operating temperature, the state of

be recharged from the high voltage traction batteries. charge and recharging. The control system also in-

The electrical supply to the PEC is connected and corporates a diagnostic data recorder which stores

166