Page 170 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 170

Battery/fuel-cell EV design packages CHAPTER 6.1

Fig. 6.1-25 Liquid hydrogen or reformed fuel: (a) Renault cryogenic storage: (b) Arthur D. Little reformer.

of 145 km/h and a range of 450 km. Fuel consumption is with the design of a stack which produced 1000 watts/

equivalent to 88 mpg and torque response to throttle litre, ten times the 1990 state of the art. Cell energy

movement is virtually instantaneous. While the first conversion efficiency, from chemical energy to electricity,

prototype weighs 1580 kg, the target weight is 1320 kg, is about 50% and the cell does not ‘discharge’ in the

just 150 kg above the standard A-class. Tank to wheel manner of a conventional storage battery. Electrodes are

efficiency is quoted as 40% now, with 88% in prospect made from porous carbon separated by the porous ion-

for a vehicle with a reformer instead of compressed conduction electrolyte membrane. It is both an electron

hydrogen. The American Methanol Institute is predicting insulator and proton conductor and is impermeable to

2 million thus-fitted cars on the road by 2010 and gas. A catalyst is integrated between each electrode and

35 million by 2020. the membrane while flow field plates are placed on each

In a summer 1999 interview Ballard chief Firoz Rasul side of the membrane/electrode assembly. These have

put the cost of electricity produced by fuel cells as channels formed in their surface through which the re-

$500/kW so that car power plants between 50 and actants flow. The plates are bi-polar in a stack, forming

200 kW amount to $25–1 00 000. PEM cells operate at the anode of one cell and the cathode of the adjacent one.

80 C and employ just a thin plastic sheet as their elec- The catalyst causes the hydrogen atoms to dissociate into

trolyte. The sheet can tolerate modest pressure differ- protons and electrons. The protons are carried through to

entials across it, which can increase power density. the cathode and the free electrons conducted as a usable

Ballard’s breakthrough in power density came in 1995 current.

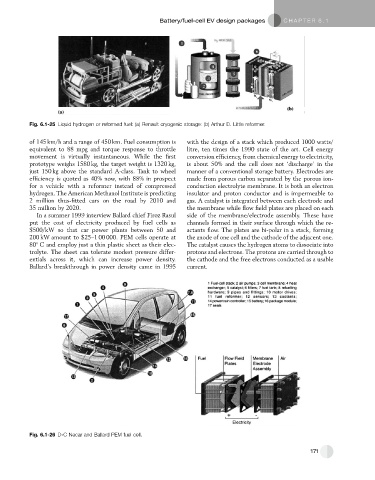

Fig. 6.1-26 D-C Necar and Ballard PEM fuel cell.

171