Page 259 - Battery Reference Book

P. 259

Silver oxide-zinc primary batteries 2013

20.1 Silver oxide-zinc primary seal. Mixtures of silver oxide and manganese dioxide

batteries may be tailored to provide a flat discharge curve or

increased service hours. The separator in the silver

The are two tylpes of silver oxide cell: one has a oxide system must retain silver soluble species pro-

cathode of monovalent silver oxide (Ag20) and the duced by chemical dissolution of the oxide, and a mul-

other type uses divalent silver oxide (Ago). The latter tiple layer separator of low-porosity film achieves this.

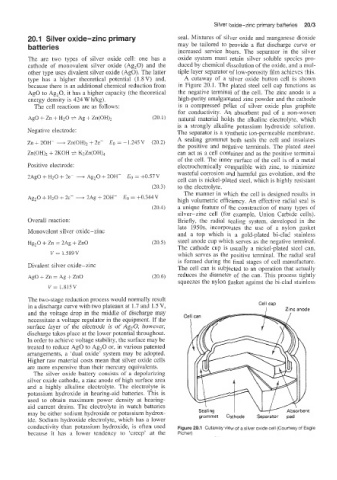

type has a highier theoretical potential (1.8 V) and, A cutaway of a silver oxide button cell is shown

because there is an additional chemical reduction from in Figure 20.1. The plated steel cell cap functions as

Ago to Ag,O. it has a higher capacity (the theoretical the negative terminal of the cell. The zinc anode is a

energy density is 424 W fig). high-purity amalgamated zinc powder and the cathode

The cell reactions are as follows: is a compressed pellet of silver oxide plus graphite

for conductivity. An absorbent pad of a non-woven

AgO + Zn + H20 + Ag + Zn(OH)2 (20.1) natural material holds the alkaline eiectrolyte, which

is a strongly alkaline potassium hydroxide solution.

Negative electrode: The separator is a synthetic ion-permeable membrane.

Zn + 2OK + &(OH), + 2e- Eo = -1.245V (20.2) A sealing grommet both seals the cell and insulates

the positive and negative terminals. The plated steel

Zn(OH), + 2KOH + KZZn(OH), can act as a cell container and as the positive terminal

of the cell. The inner surface of the cell is of a metal

Positive electrode: electrochemically compatible with zinc, to minimize

2Ag0 + H20 + 2e- + Ag,O + 2OH- Eo = +OS7 V wasteful corrosion and harmful gas evolution, and the

cell can is nickel-plated steel, which is highly resistant

(20.3) to the electrolyte.

The manner in which the cell is designed results in

AgzO + IH20 + 2t- + 2Ag + 20H- Eo = +0.344V

high volumetric efficiency. An effective radial seal is

(20.4) a unique feature of the construction of many types of

silver-zinc cell (for example, Union Carbide cells).

Overall reaction: Briefly, the radial sealing system, developed in :he

late 1950s, incorporates the use of a nylon gasket

Monovalent silver oxide-zinc

and a top which is a gold-plated bi-clad stainless

NgzO + Zn = 2Ag + ZnO (20.5) steel anode cup which serves as the negative terminal.

The cathode cup is usually a nickel-plated steel can.

v = 1.589V which serves as the positive terminal. The radial seal

is formed during the final stages of cell manufacture.

Divalent silver oxide-zinc The cell can is subjected to an operation that actually

AgO + Zn = Ag i- ZnO (20.6) reduces the diameter of the can. This process tightly

squeezes the nylon gasket against the bi-clad stainless

V = 1.815V

The two-stage reduction process would normally result

in a discharge curve with two plateaux at 1.7 and 1.5 V, Cell cap Zinc anode

I

and the voltage drop in the middle of discharge may

necessitate a voltage regulator in the equipment. If the

surface Iayer of the electrode is of Ag20, however,

discharge takes place at the lower potential throughout.

In order to achieve voltage stability, the surface may be

treated to reduce Ago to Ag20 or, in various patented

arrangements, a ‘dual oxide’ system may be adopted.

Higher raw material costs mean that silver oxide cells

are more expensive than their mercury equivalents.

The silver oxide battery consists of a depolarizing

silver oxide cathode, a zinc anode of high surface area

and a highly alkaline electrolyte. The electrolyte is

potassium hydroxide in hearing-aid batteries. This is

used to obtain maximum power density at hearing-

aid current drains. The electrolyte in watch batteries

may be either sodium hydroxide or potassium hydrox- Sealing

ide. Sodium hydroxide electrolyte, which has a lower grommet Cathode Separator pad

conductivity than potassium hydroxide, is often used Figure 20.1 Cutaway view of a silver oxide cell (Courtesy of Eagle

because it has a lower tendency to ’creep’ at the Picher)