Page 254 - Battery Reference Book

P. 254

19/20 Nickel batteries

Table 19.5 Nickel-hydrogen cell electrochemistry

Operation mode Electrochemistr?,

Normal

Charge

Nickel electrode Ni(OH)2 + OH- W NiOOH + H2O + e-

Discharge

Charge

aH2

Hydrogen H20 + e- e + OH-

Discharge

Charge

Net reaction Ni(0H)z ___\ NiOOH + 4H2

Discharge

Overcharge

Nickel electrode 20H- --f $02 + H2O + 2e-

Hydrogen electrode 2 HzO + 2e- .+ H2 + 20H-

Net reaction H2 + a02 .+ H2O + HEAT

Overdischarge (cell reversal)

Nickel electrode H20 + e- .+ $Hz +OH-

Hydrogen electrode OH- + bH2 .+ H2O + e-

&;ressure vessel Gas screen wick. Hence, electrolyte which leaves the stack dur-

ing cycling will be wicked back. The nickel electrode

Wall wick (not shown) consists of a sintered nickel powder plaque containing

a nickel screen substrate, which is electrochemically

Hydrogen impregnated with nickel hydroxide active material by

electrode the Pickett process. The gas screens are polypropylene.

Separator The electrolyte is a 31% aqueous solution of potassium

Nickel hydroxide.

stack electrode

Hydrogen gas 19.3 Nickel-zinc secondary batteries

These batteries are not yet available in a sealed form.

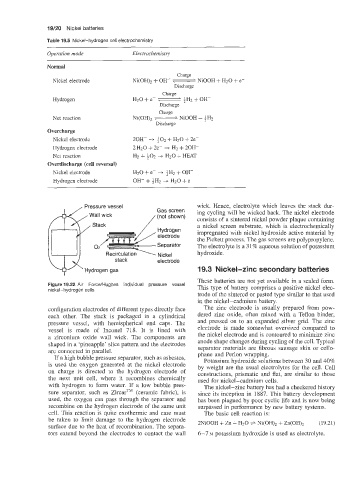

Figure 19.22 Air Force/Hughes individual pressure vessel This type of battery comprises a positive nickel elec-

nickel-hydrogen cells

trode of the sintered or pasted type similar to that used

in the nickel-cadmium battery.

configuration electrodes of different types directly face The zinc electrode is usually prepared from pow-

each other. The stack is packaged in a cylindrical dered zinc oxide, often mixed with a Teflon binder,

pressure vessel, with hemispherical end caps. The and pressed on to an expanded silver grid. The zinc

vessel is made of Inconel 718. It is lined with electrode is made somewhat oversized compared to

a zirconium oxide wall wick. The components are the nickel electrode and is contoured to minimize zinc

shaped in a ‘pineapple’ slice pattern and the electrodes anode shape changes during cycling of the cell. Typical

separator materials are fibrous sausage skin or cello-

are connected in parallel. phane and Perlon wrapping.

If a high bubble pressure separator, such as asbestos, Potassium hydroxide solutions between 30 and 40%

is used the oxygen generated at the nickel electrode by weight are the usual electrolytes for the cell. Cell

on charge is directed to the hydrogen electrode of constructions, prismatic and flat, are similar to those

the next unit cell, where it recombines chemically used for nickel-cadmium cells.

with hydrogen to form water. If a low bubble pres- The nickel-zinc battery has had a checkered history

sure separator, such as ZircarTM (ceramic fabric), is since its inception in 1887. This battery development

used, the oxygen can pass through the separator and has been plagued by poor cyclic life and is now being

recombine on the hydrogen electrode of the same unit surpassed in performance by new battery systems.

cell. This reaction is quite exothermic and care must The basic cell reaction is:

be taken to limit damage to the hydrogen electrode 2NiOOH + Zn + H20 + Ni(OH)2 + Zn(0H)z (19.21)

surface due to the heat of recombination. The separa-

tors extend beyond the electrodes to contact the wall 6-7 M potassium hydroxide is used as electrolyte.