Page 253 - Battery Reference Book

P. 253

Nickel-hydrogen and silver-hydrogen secondary batteries 19/19

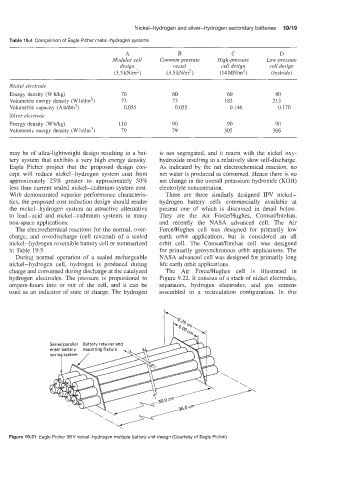

Table 19.4 Comparison of Eagle Picher metal-hydrogen systems

A B C ID

Modular cell Common pressure High-pressure Low-pressure

design vessel cell design cell design

(3.5 m/rn2) (3.5w/m2) (14 MN/m2) (hydride)

Nickel electmde

Energy density (W h/kg) IO 60 60 60

Volumetric energy density (W h/dm3) 73 13 183 213

Volumetric capacity (A h/dm3) 0.055 0.055 0.146 0.170

Silver electrode

Energy density (W Mkg) 110 90 90 90

Volumetric energy density (W h/dm3) 79 79 305 366

may be of ultra-lightweight design resulting in a bat- is not segregated, and it reacts with the nickel oxy-

tery system that exhibits a very high energy density. hydroxide resulting in a relatively slow self-discharge.

Eagle Picher project that the proposed design con- As indicated by the net electrochemical reaction, no

cept will reduce nickel-hydrogen system cost from net water is produced or consumed. Hence there is no

approximately 25% greater to approximately 50% net change in the overall potassium hydroxide (KOH)

less than current sealed nickel-cadmium system cost. electrolyte concentration.

With demonstrated superior performance characteris- There are three similarly designed IPV nickel-

tics, the proposed cost reduction design should render hydrogen battery cells commercially available at

the nickel-hydrogen system an attractive alternative present one of which is discussed in detail below.

io lead-acid and nickel-cadmium systems in many They are the Air ForceEIughes, CornsatIIntelsat,

non-space applications. and recently the NASA advanced cell. The Air

The electrochemical reactions for the normal, over- Forcemughes cell was designed for primarily low

charge, and overdischarge (cell reversal) of a sealed earth orbit applications, but is considered an all

nickel-hydrogen reversible battery cell or summarized orbit cell. The ComsatAntelsat cell was designed

in Table 19.5. for primarily geosynchronous orbit applications. The

During normal operation of a sealed rechargeable NASA advanced cell was designed for primarily long

nickel-hydrogen cell, hydrogen is produced during life earth orbit applications.

charge and consumed during discharge at the catalyzed The Air Forcemughes cell is illustrated in

hydrogen electrodes. The pressure is proportional to Figure 9.22. It consists of a stack of nickel electrodes,

ampere-hours into or out of the cell, and it can be separators, hydrogen electrodes, and gas screens

used as an indicator of state of charge. The hydrogen assembled in a recirculation configuration. In this

Figure 19.21 Eagle Picher 36V nickel-hydrogen multiple battery unit design (Courtesy of Eagle Picher)