Page 265 - Battery Reference Book

P. 265

Alkaline manganese secondary batteries 2113

21.1 Alkaline manganese primary powder inserted. Contact to the negative terminal at

batteries the base of the battery is by an internal metal contact.

This design gives a high current density per unit vol-

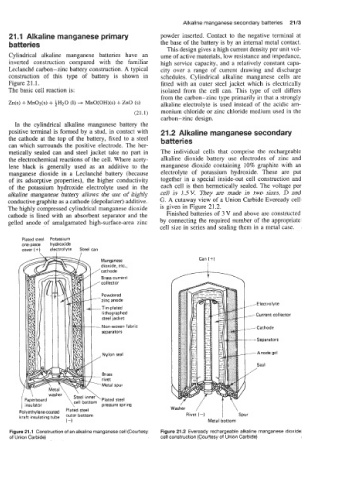

Cylindrical alkaline manganese batteries have an ume of active materials, low resistance and impedance,

inverted construction compared with the familiar high service capacity, and a relatively constant capa-

LeclanchC carbon-zinc battery construction. A typical city over a range of current drawing and discharge

construction of this type of battery is shown in schedules. Cylindrical alkaline manganese cells are

Figure 21.1. fitted with an outer steel jacket which is electrically

The basic cell reaction is: isolated from the cell can. This type of cell differs

from the carbon-zinc type primarily in that a strongly

Zn(s) + MnOz(s) + f HzO (1) + MnO(OH)(s) + ZnO (s) alkaline electrolyte is used instead of the acidic am-

(21.1) monium chloride or zinc chloride medium used in the

carbon-zinc design.

In the cylindrical alkaline manganese battery the

positive terminal is formed by a stud, in contact with 21.2 Alkaline manganese secondary

the cathode at the top of the battery, fixed to a steel batteries

can which surrounds the positive electrode. The her-

metically sealed can and steel jacket take no part in The individual cells that comprise the rechargeable

the electrochemical reactions of the cell. Where acety- alkaline dioxide battery use electrodes of zinc and

lene black is generally used as an additive to the manganese dioxide containing 10% graphite with an

manganese dioxide in a LeclanchC battery (because electrolyte of potassium hydroxide. These are put

of its adsorptive properties), the higher conductivity together in a special inside-out cell construction and

of the potassium hydroxide electrolyte used in the each cell is then hermetically sealed. The voltage per

alkaline manganese battery allows the use of highly cell is 1.5V. They are made in two sizes, D and

conductive graphite as a cathode (depolarizer) additive. G. A cutaway view of a Union Carbide Eveready cell

The highly compressed cylindrical manganese dioxide is given in Figure 21.2.

cathode is lined with an absorbent separator and the Finished batteries of 3 V and above are constructed

gelled anode of amalgamated high-surface-area zinc by connecting the required number of the appropriate

cell size in series and sealing them in a metal case.

Plated steel Potassium

one.piece hydroxide

cover (+) electrolyte Steel can

Can (+)

Current collector

Paperboard cell

insu I at or Dressure spring Washer / I

lyethylenecoated ‘Iated steel

aft insulating tube Outer bottom Rivet (-) ‘Spur

(-1 Metal bottom

Figure 21.1 Construction of an alkaline manganese cell (Courtesy Figure 21.2 Eveready rechargeable alkaline manganese dioxide

of Union Carbide) cell construction (Courtesy of Union Carbide)