Page 444 - Battery Reference Book

P. 444

Lead-acid batteries 4313

An effort to develop a practical electric vehicle is con- costs of the battery-powered vehicle vary from 60% to

suming a significant portion of the technical resources as low as 30% of those of petrol and diesel-powered

of the technically advanced nations. Its projected vehicles.

impact upon the environment is well known; an elec-

tric vehicle would contribute to a major reduction in 43.1.2 The Silent Rider Programme

emission pollutants, particularly in metropolitan areas.

In addition, as natural energy resources become more Silent Rider is an electric bus. It will carry 50 people

scarce, it has been and will continue to be necessary at 40 milesh over a 40-mile range on one charge.

to develop new energy sources and to centralize the Trials are being conducted in collaboration with bus

use of old resources for greater efficiency. In virtu- companies in two counties, Lancashire and Cheshire.

ally all of thesle new and changing energy systems, Figures 43.1 and 43.2 show the layout of this bus.

the conversion or usable output is in the form of elec- The 330 V battery in this vehicle weighs 4.4 tons, and

trical energy. The ability of an electric vehicle to use consists of 165 cells, each with a capacity of 329Ah.

this future primary energy source directly may well Investigations by Chloride Batteries have shown that

overshadow its more familiar environmental benefits. nearly 50% of buses on city centre journeys during

peak periods cover less than 25 miles, with a further

40% covering no more than 40 miles. The shaded areas

43.1 Lead-acid batteries in Figure 43.3 show the potential for a battery-operated

The starting point of power sources for electric vehicles bus with a range of 40 miles.

was, of course, the lead-acid battery. Because of their A more recent application of lead-acid batteries

relatively low power density, compared with other to electric vehicle propulsion is the General Motors

types of battery which are now becoming available, G-van. This vehicle was developed under the EPRI

other types of batteries are now being considered Transportation Plan and is now marketed. The vehicle

for this application. The low power density of the has a range of 90km in simulated city driving, a top

lead-acid system puts severe limitations on the range speed of 52 mph and an acceleration from 0 to 30 rnph

that can be achieved between battery charges, although in 13 seconds. It was planned to introduce up to 10,000

the restrictions regarding acceleration and maximum of these vehicles in the Los Angeles areas between

speed are not as lirriting as they once were. 1991 and 1996.

The lead-acid battery should not be dismissed Performance data on the 6V monobloc cells is

lightly as a power source for electric vehicles. It is, listed below:

in fact, the only type of battery being used in large- under 40 kw

scale prototype vehicle trials. Chloride Batteries UK Load, per monobloc

are currently conducting several such trials. Peak power 1.0

per cell:

fully charged 112 Wkg

43.1.1 The Silent Carrier Programme 80% discharged 57 wkg

Silent Can-ier is a 1.Xton urban delivery van. The General Motors are continuing to develop the Impact

earlier versions of this vehicle had a maximum range lightweight electric car. This vehicle is capable of

of 35-40 miles and this has since been improved. The accelerations of 0 to 60mph in 8 seconds and has a

maximum speed is 49 milesh and the hill climbing top speed of 100 mph. It is fitted with 3210 V lead acid

ability is 1 in 8. Although the basic cost of early batteries weighing 396 kg.

production models will be a little higher than that Developments in flat or tubular plate designs for

of vehicles with internal combustion engines, running lead-acid electric vehicle traction has in recent years

costs will be lower. It is claimed that the maintenance concentrated on improving energy density and power

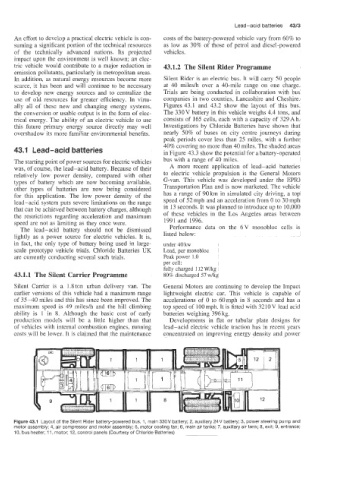

Figure 43.1 Layout of the Silent Rider battery-powered bus. 1, main 330V battery; 2, auxiliary 24V battery; 3, power steering pump and

motor assembly; 4, air compressor and motor assembly; 5, motor cooling fan: 6, main air tanks; 7, auxiliary air tank; 8, exit: 9, entrance;

10, bus heater: 11, motor: 12, control panels (Courtesy of Chloride Batteries)