Page 136 - Biaxial Multiaxial Fatigue and Fracture

P. 136

Long-LVe Multiaxial Fatigue of a Nodular Gmphite Cast Iron 121

22. Endo, M. and Murakami, Y. (1987) Effects of an artificial small defect on torsional

fatigue strength of steels, J Eng. Mat. Tech. 109, pp. 124-129.

23. Beretta, S. and Murakami, Y. (1998) The stress intensity factor for small cracks at

micro-notches under torsion, In: ECF 12 Fracture from defects, M. W. Brown, E. R. de

10s Rios and K. J. Miller (Eds.), EMAS, pp. 55-60.

24. Wallin, K. (1999) The probability of success using deterministic reliability, In: Fatigue

Design and Reliability, ESIS Publication 23, G. Marquis and J. Solin (Eds.), Elsevier

Science, Oxford, pp. 39-50.

25. Murakami, Y. (1994) Inclusion rating by statistics of extreme values and its application

to fatigue strength prediction and quality control of materials, J Res. National Inst Std

Tech. 99, pp. 345-351.

26. Brown M. W. and Miller, K. J. (1985) Mode I fatigue crack growth under biaxial stress

at room and elevated temperature, In: Multiaxial Fatigue, ASTM STP 853, K. J. Miller

and M. W. Brown (Eds.), ASTM, Philadelphia, pp. 135-152.

27. Liu, A.F., Allison, J.A., Dittmer, D.F., and Yamane, J. (1979) Effect of biaxial stresses

on crack growth, In: Fracture Mechanics, ASTM STP 677, C. W. Smith (Ed.), pp. 5-22.

28. Miller, K. J. (199 1) 27'h John Player lecture: Metal fatigue - past current and future,

Proc. Inst. Mech. Engineers, London, 14 p.

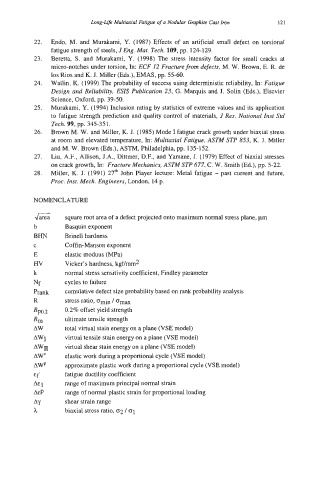

NOMENCLATURE

Jarea square root area of a defect projected onto maximum normal stress plane, pm

b Basquin exponent

BHN Brinell hardness

C Coffin-Manson exponent

E elastic moduus (MPa)

HV Vicker's hardness, kgf/mm2

k normal stress sensitivity coefficient, Findley parameter

Nf cycles to failure

Prank cumulative defect size probability based on rank probability analysis

R stress ratio, Cmin / Omax

Rpo.2 0.2% offset yield strength

Rm ultimate tensile strength

AW total virtual stain energy on a plane (VSE model)

AWI virtual tensile stain energy on a plane (VSE model)

Awn virtual shear stain energy on a plane (VSE model)

Awe elastic work during a proportional cycle (VSE model)

AWp approximate plastic work during a proportional cycle (VSE model)

fatigue ductility coefficient

Et

1 range of maximum principal normal strain

AEP range of normal plastic strain for proportional loading

AY shear strain range

h biaxial stress ratio, a2 / 01