Page 201 - Biaxial Multiaxial Fatigue and Fracture

P. 201

Estimation of the Fatigue Life of High Strength Steel Under ... 185

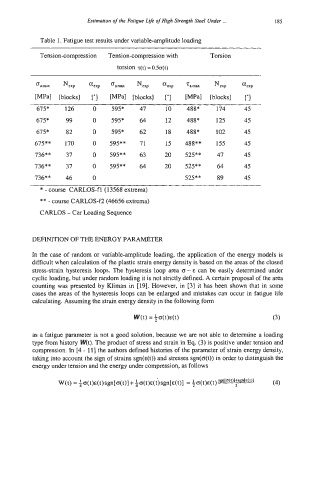

Table 1. Fatigue test results under variable-amplitude loading

Tension-compression Tension-compression with Torsion

torsion qt) = O.%(t)

damax Nexp aexp dam Nap aexp ramax Nexp aexp

[blocks] ["I [MPal [blocks] ['I [MPal [blocks] ['I

675* 126 0 595* 47 10 488* 174 45

675* 99 0 595* 64 12 488" 125 45

675* 82 0 595* 62 18 488" 102 45

675** 170 0 595** 71 15 488** 155 45

736** 37 0 595** 63 20 525** 47 45

736** 37 0 595** 64 20 525** 64 45

136** 46 0 525** 89 45

* - course CARLOS-fl (13568 extrema)

** - course CARLOSf2 (46656 extrema)

CARLOS - Car Loading Sequence

DEFINlTION OF THE ENERGY PARAMETER

In the case of random or variable-amplitude loading, the application of the energy models is

difficult when calculation of the plastic strain energy density is based on the areas of the closed

stress-strain hysteresis loops. The hysteresis loop area a - E can be easily determined under

cyclic loading, but under random loading it is not strictly defined. A certain proposal of the area

counting was presented by Kliman in [19]. However, in 131 it has been shown that in some

cases the areas of the hysteresis loops can be enlarged and mistakes can occur in fatigue life

calculating. Assuming the strain energy density in the following form

as a fatigue parameter is not a good solution, because we are not able to determine a loading

type from history W(t). The product of stress and strain in J3q. (3) is positive under tension and

compression. In [4 - 111 the authors defined histories of the parameter of strain energy density,

taking into account the sign of strains sgn(e(t)) and stresses sgn(a(t)) in order to distinguish the

energy under tension and the energy under compression, as follows