Page 305 - Biaxial Multiaxial Fatigue and Fracture

P. 305

The Background of Fatigue Limit Ratio of Torsional Fatigue to Rotating Bending Fatigue in ... 289

(-1~m) like a point, and gradually grows as the number of cycles N increases. Then the

crack does not stop propagating due to the work softening effect [16], which finally causes the

specimen to break. This phenomenon is quite different from the case of an annealed carbon

steel, where fatigue process can clearly be divided into crack initiation and crack propagation

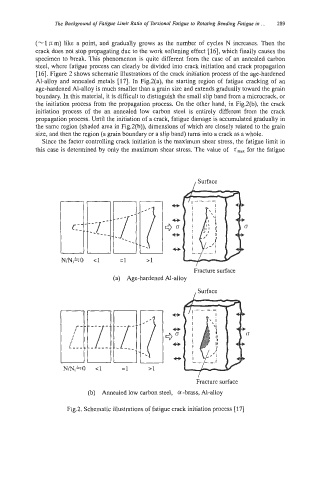

[16]. Figure 2 shows schematic illustrations of the crack initiation process of the age-hardened

Al-alloy and annealed metals [17]. In Fig.2(a), the starting region of fatigue cracking of an

age-hardened Al-alloy is much smaller than a grain size and extends gradually toward the grain

boundary. In this material, it is difficult to distinguish the small slip band from a microcrack, or

the initiation process from the propagation process. On the other hand, in Fig.2(b), the crack

initiation process of the an annealed low carbon steel is entirely different from the crack

propagation process. Until the initiation of a crack, fatigue damage is accumulated gradually in

the same region (shaded area in Fig2(b)), dimensions of which are closely related to the grain

size, and then the region (a grain boundary or a slip band) turns into a crack as a whole.

Since the factor controlling crack initiation is the maximum shear stress, the fatigue limit in

this case is determined by only the maximum shear stress. The value of z,,, for the fatigue

/ Surface

N/Ni=O c1 =I

(a) Age-hardened Al-alloy

, Surface

Fracture surface

(b) Annealed low carbon steel, cx -brass, Al-alloy

Fig.2. Schematic illustrations of fatigue crack initiation process [17]