Page 225 - Cascade_Biocatalysis_Integrating_Stereoselective_and_Environmentally_Friendly_Reactions

P. 225

9.1 Introduction 201

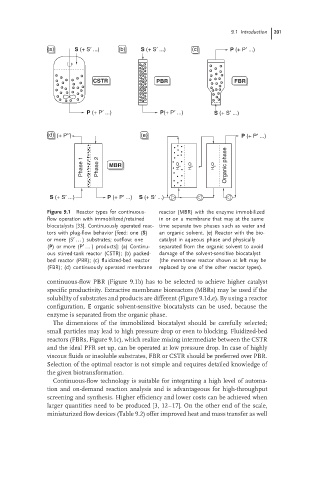

(a) S (+ S′ ...) (b) S (+ S′ ...) (c) P (+ P′ ...)

CSTR PBR FBR

P (+ P′ ...) P(+ P′ ...) S (+ S′ ...)

(d) (+ P′′) (e) P (+ P′ ...)

Phase 1 Phase 2 MBR H 2 O H 2 O H 2 O Organic phase

S (+ S′ ...) P (+ P′ ...) S (+ S′ ...)

Figure 9.1 Reactor types for continuous- reactor (MBR) with the enzyme immobilized

flow operation with immobilized/retained in or on a membrane that may at the same

biocatalysts [33]. Continuously operated reac- time separate two phases such as water and

tors with plug-flow behavior [feed: one (S) an organic solvent. (e) Reactor with the bio-

′

or more (S … ) substrates; outflow: one catalyst in aqueous phase and physically

′

(P) or more (P … ) products]: (a) Continu- separated from the organic solvent to avoid

ous stirred-tank reactor (CSTR); (b) packed- damage of the solvent-sensitive biocatalyst

bed reactor (PBR); (c) fluidized-bed reactor (the membrane reactor shown at left may be

(FBR); (d) continuously operated membrane replaced by one of the other reactor types).

continuous-flow PBR (Figure 9.1b) has to be selected to achieve higher catalyst

specific productivity. Extractive membrane bioreactors (MBRs) may be used if the

solubility of substrates and products are different (Figure 9.1d,e). By using a reactor

configuration, E organic solvent-sensitive biocatalysts can be used, because the

enzyme is separated from the organic phase.

The dimensions of the immobilized biocatalyst should be carefully selected;

small particles may lead to high pressure drop or even to blocking. Fluidized-bed

reactors (FBRs, Figure 9.1c), which realize mixing intermediate between the CSTR

and the ideal PFR set up, can be operated at low pressure drop. In case of highly

viscous fluids or insoluble substrates, FBR or CSTR should be preferred over PBR.

Selection of the optimal reactor is not simple and requires detailed knowledge of

the given biotransformation.

Continuous-flow technology is suitable for integrating a high level of automa-

tion and on-demand reaction analysis and is advantageous for high-throughput

screening and synthesis. Higher efficiency and lower costs can be achieved when

larger quantities need to be produced [3, 12–17]. On the other end of the scale,

miniaturized flow devices (Table 9.2) offer improved heat and mass transfer as well