Page 292 - Biofuels Refining and Performance

P. 292

Fuel Cells 271

life of 40,000 h with reasonable performance (degradation rate ∆V lifetime

(mV) 2 mV/1000 h) [3, 23].

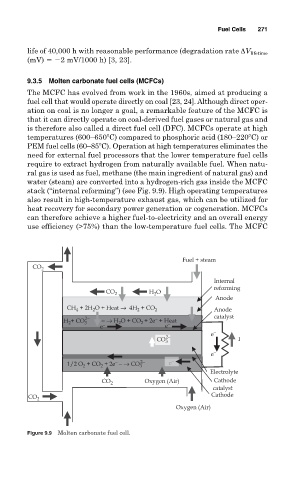

9.3.5 Molten carbonate fuel cells (MCFCs)

The MCFC has evolved from work in the 1960s, aimed at producing a

fuel cell that would operate directly on coal [23, 24]. Although direct oper-

ation on coal is no longer a goal, a remarkable feature of the MCFC is

that it can directly operate on coal-derived fuel gases or natural gas and

is therefore also called a direct fuel cell (DFC). MCFCs operate at high

temperatures (600–650 C) compared to phosphoric acid (180–220 C) or

PEM fuel cells (60–85 C). Operation at high temperatures eliminates the

need for external fuel processors that the lower temperature fuel cells

require to extract hydrogen from naturally available fuel. When natu-

ral gas is used as fuel, methane (the main ingredient of natural gas) and

water (steam) are converted into a hydrogen-rich gas inside the MCFC

stack (“internal reforming”) (see Fig. 9.9). High operating temperatures

also result in high-temperature exhaust gas, which can be utilized for

heat recovery for secondary power generation or cogeneration. MCFCs

can therefore achieve a higher fuel-to-electricity and an overall energy

use efficiency (>75%) than the low-temperature fuel cells. The MCFC

CO 2

Internal

reforming

CO 2 H O

2

Anode

CH + 2H O + Heat → 4H + CO 2 Anode

2

2

4

2− − catalyst

H +CO 3 − → H O + CO + 2e + Heat

2

2

−

2

e e − e e

2− e −

CO 3 I

e −

−

1/2 O + CO + 2e − → CO 3 2− e −

2

2

Electrolyte

CO 2 Oxygen (Air) Cathode

catalyst

CO 2 Cathode

Oxygen (Air)

Figure 9.9 Molten carbonate fuel cell.